Slate Group Boosts Efficiency and Quality with Lithrone G40P advance

U.S., Slate Group | Lithrone G40P advance [GL-840P-A]

10 October 2024

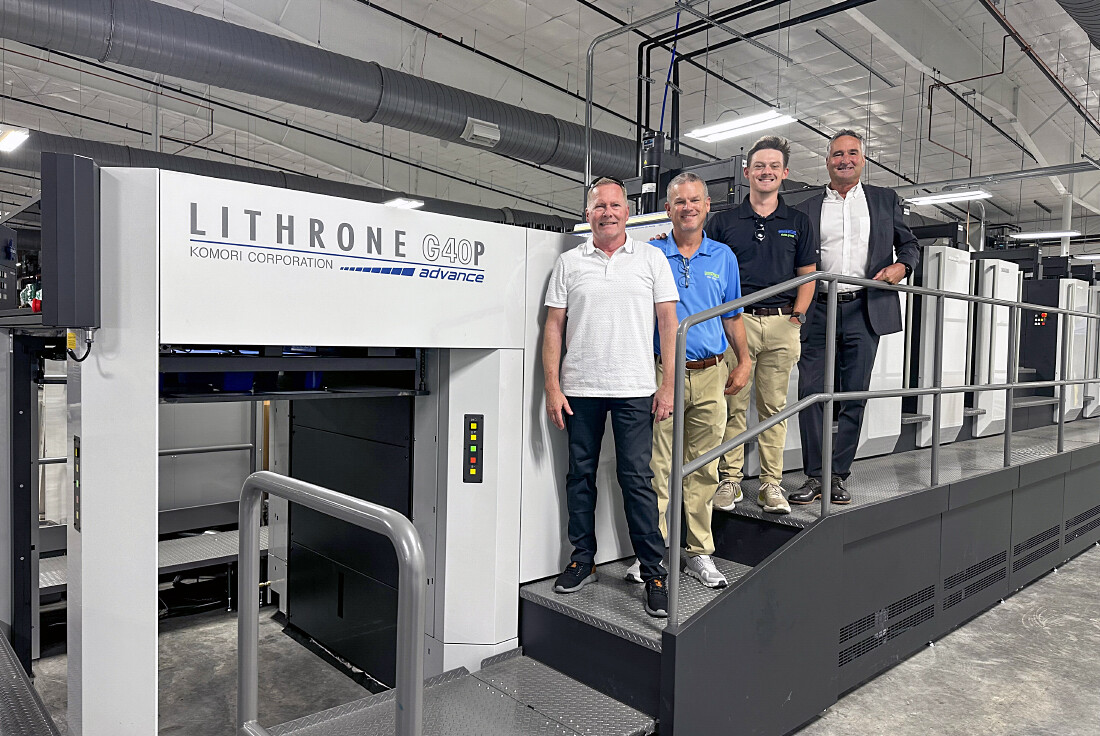

Founded almost four decades ago, Slate Group has grown exponentially, from an 18,000-square-foot facility to a nearly 100,000-square-foot operation in the last 11 years. The company has doubled its workforce from 52 to 125 employees and diversified its customer base across a range of fields, including agriculture, higher education, healthcare, financial services, and retail. The company operates two daily 12-hour press shifts, with each shift working for seven consecutive days and then having seven days off to rest. Notably, Slate Group generates 88 percent of its revenue from clients outside its region, demonstrating its broad market command. The company recently installed an eight-color Lithrone G40P advance.

Slate Group's growth necessitated expansion of its production capabilities to meet increasing demand and maintain its high standards of quality and efficiency. According to Don Denny, Slate Group's owner, "The decision to invest in a new eight-color Lithrone G40P advance H-UV L (LED) press was driven by the need to handle our growing volume of publication work more efficiently. We often faced weekends with over 200 hours of booked press time, and our existing 40-inch presses were running 24/7 without enough capacity."

Additionally, this investment opens the door for Slate Group to enter the packaging industry, as the existing 40-inch presses will now be available for that work. This strategic move not only addresses current operational demands but also positions the company for future growth and diversification.

Smooth installation

The installation of the new Komori press is going very well. As Don Denny recounted, "This has been one of the smoothest press installations we've ever had. The riggers were able to finish a day early, and there were no significant issues during the setup." This seamless installation process will minimize downtime and ensure a quick transition to full production.

"Turning a 44-hour job into a 22-hour job on the new press will make a huge difference in our production capacity."

- Don Denny

Impact on operations

The new eight-color Lithrone G40P advance will significantly enhance Slate Group's production efficiency. Denny noted, "Over the last six months, our two 40-inch presses have produced over 21 million impressions. With the new perfector, we expect to increase our output even further while reducing makeready times and paper waste."

The H-UV L (LED) technology integrated into the new press will be a game-changer for Slate Group. "The H-UV L (LED) system will allow us to print on nearly any stock and move straight into binding without the need for drying time," explained Denny. "This will drastically reduce our turnaround times, especially for high-end publications on uncoated stock."

Moreover, the new eight-color Lithrone G40P advance will free up one of the existing 40-inch presses, enabling Slate Group to explore new opportunities in the packaging industry. "Now that we've got the eight-color Lithrone G40P advance press, packaging is on our radar," Denny said. "It'll allow one of the other 40-inch presses some free time, and we're going to start moving into packaging."

Significant savings

Slate Group will also benefit from significant cost savings with the new press. "When we analyzed the effects on the entire printing and finishing process, we realized that the higher cost of H-UV L (LED) inks is far outweighed by the improved efficiencies. We get superior quality and no time limitations for finishing," Denny emphasized. "We will now produce high-quality prints faster, which translates into cost savings for our clients."

Slate Group is taking a leading sustainability position by implementing measures such as using 10 percent post-consumer recycled paper and using less energy via the LED UV print process. The company recycles all printing plates and reduces waste sheets through investments in new press technology from Komori. "We focus on efficiency and cost-effectiveness, but we also ensure our operations are as sustainable as possible within those constraints," Denny added.

Benefits for workforce and clients

The new press will also have a positive impact on Slate Group's workforce. The advanced technology and automation will allow for better cross-training and skill development. "Our press operators, many of whom are in their early 30s, have always embraced new technology and taken ownership of the equipment," said Trey Laverty, Slate Group's sales manager. "This has fostered a culture of innovation and continuous improvement."

Slate Group's clients have always benefited from faster turnaround times and enhanced print quality. "We've had clients who are amazed at how quickly we can turn around complex jobs without compromising on quality," Laverty noted. "This has strengthened our relationships and positioned us as a trusted partner for their marketing and printing needs."

"Our press operators, many in their early 30s, have always embraced new technology and taken ownership of the equipment, fostering a culture of innovation."

- Trey Laverty

Strong outlook

Looking ahead, Slate Group is poised for continued growth and innovation. The company plans to explore new market segments, such as packaging, by leveraging its expanded capabilities. "With the new Lithrone G40P advance, we can now handle smaller-run web-to-print jobs in-house, opening up new opportunities for us," Denny explained.

"We're committed to keeping our presses and bindery busy, and we're exploring all avenues to ensure we remain competitive and responsive to market demands. By growing and investing in our business, we are not only enhancing our capabilities but also creating jobs and fostering economic growth in our local community in Lubbock, Texas. Our success contributes directly to the prosperity of the area, and we take pride in making a positive impact on the lives of our employees and neighbors," Denny emphasized.

"We use 10 percent post-consumer recycled paper and recycle our printing plates, balancing efficiency with sustainability."

- Don Denny

Conclusion

The installation of the new eight-color Lithrone G40P advance at Slate Group marks a significant milestone in the company's journey. By enhancing production efficiency, reducing turnaround times, and improving print quality, Slate Group is well-equipped to meet the evolving needs of its diverse client base.