KGC Renovation: Evolving into an Open Innovation Hub

Toward the Smart Factory that Integrates Workers and Automation Systems

22 January 2025

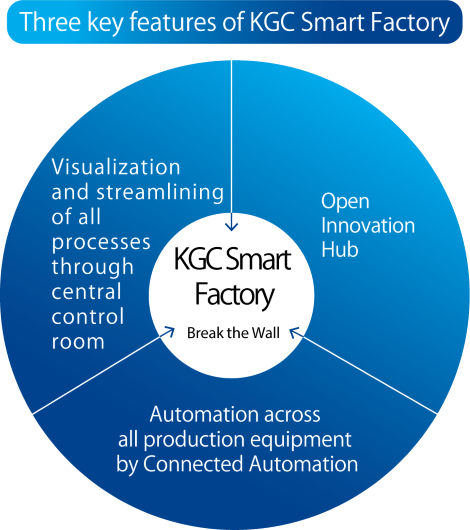

The Komori Graphic Technology Center (KGC) has evolved according to printing industry needs and was transformed into the KGC Smart Factory in October 2024. This article introduces the KGC Smart Factory, which is newly equipped with a central control room where workers and automation systems are integrated.

The Smart Factory: A Space for Development, Inspection, and Innovation

The printing industry is facing challenges such as the diversification of demand, including short-run and short-delivery production, rising material and energy costs, and difficulties in securing human resources. In order to secure stable profits and contribute to a sustainable society in this environment, flexible responses and transformation are required.

Komori views advancing smart factory initiatives to enhance not only the productivity of individual machines but also the overall productivity of printing plants as a pivotal step in revolutionizing the industry. Under a long-term vision, Komori is committed to achieving smart factories that are environmentally friendly, operable by anyone, and safe, positioning this as a critical challenge to address.

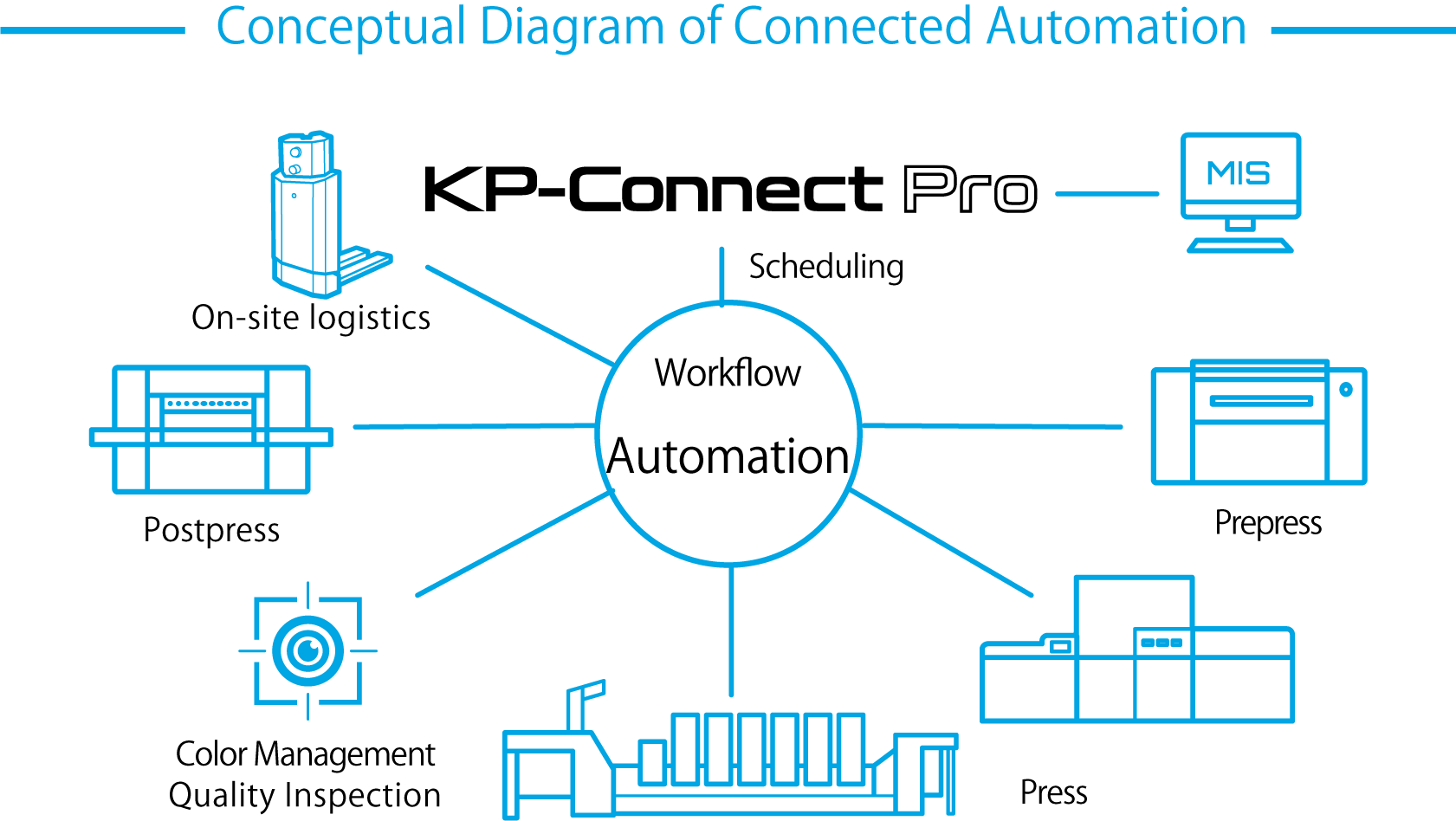

Komori's concept of a smart factory involves Connected Automation to integrate production equipment. At its core is the KP-Connect Pro manufacturing execution system, which connects automated equipment to achieve visualization, automation, and streamlining, enabling maximized productivity, environmental responsiveness, and solutions for labor shortages.

In this renovation, a virtual smart factory for printing plants was established on-site to create an environment that accelerates value-creation initiatives. Specifically, this environment serves as a space for developing and validating solutions under production-like conditions and fostering open innovation with customers, alliance partners, and other industries.

Central control room oversees the KGC Smart Factory

The KGC Smart Factory aims to integrate workers and automation systems, positioning people as the source of added value rather than an unmanned facility. The layout facilitates a smooth flow of people and materials while eliminating physical barriers between processes.

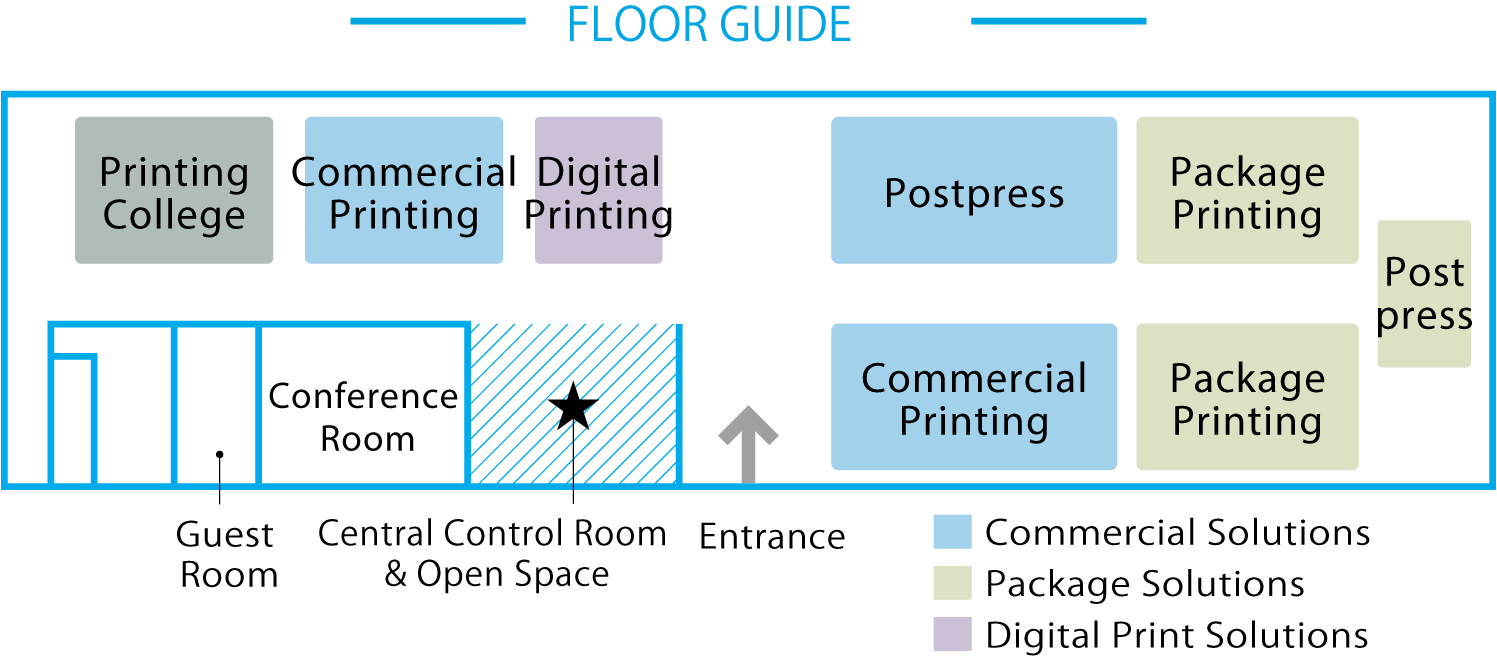

The centerpiece of the renovation is the central control room, positioned at the heart of KGC. In the central control room, which is equipped with four large monitors, needed information is automatically collected in real time via KP-Connect Pro.

This allows managers to monitor immediately the operational status of production equipment and respond quickly to abnormalities. By removing information barriers, tasks like schedule changes and production status confirmation are simplified, enabling a focus on value-added tasks and boosting the factory's overall productivity.

We are planning to develop systems that can manage all aspects of Quality, Cost, Delivery, and Energy from the central control room to meet customer needs.

Pilot testing initiated: automation of plate output and sorting

The KGC Smart Factory is now equipped with CTP systems for prepress, five offset presses and digital printing machines for press, and cutting machines and folding machines for postpress. Pilot testing has begun using these facilities. Using jobs similar to those performed by printing companies, we are verifying whether Komori's solutions function correctly and identifying any operational problems or issues.

In prepress, KP-Connect Pro is linked to an automatic plate sorting system, enabling automated plate output and plate sorting.

Currently, Konno Printing Co., Ltd. and Smart Graphics Co., Ltd. are using KP-Connect Pro, integrated with SCREEN's equipment in actual operations for prepress workflows. Please refer to the following for more details.

Fundamental functions of KGC also evolved after renovation

The three functions of KGC -- print technology research and development, demonstrations, and customer training support -- will also expand their scope from individual printing presses to the entire factory.

For example, the Demonstration Center allows customers to bring in actual jobs and use KGC equipment to verify the effectiveness of smart factory initiatives. The Printing College, which focuses on workforce development, has enhanced its curriculum to include factory-wide management, productivity improvement, and smart factory construction and operation. Printing R&D Center efforts now cover all processes, with a special focus on the development of environmentally friendly products.

KGC: An open innovation hub shaping the future of the printing industry

KGC's new role is to research, develop and provide solutions that support the realization of smart factories. However, rapid responsiveness is required to respond to the drastic changes in the environment. Achieving smart factory initiatives on a factory-wide scale also necessitates the development of solutions beyond the printing presses that are Komori's specialty.

To address these challenges, Komori will transform KGC into an open innovation hub to eliminate barriers between companies, invigorate collaboration, and strengthen partnerships with various companies. The results of development carried out with partner companies in the KP-Connect Alliance Program launched in 2016 can be seen at KGC.

Through collaboration with many companies, the new KGC Smart Factory has been established, covering all processes from prepress to offset printing, digital printing, postpress, and even the transport systems connecting each stage.

Serving as an open innovation hub, the KGC Smart Factory brings together printing companies, alliance partners, and Komori in a unified effort to shape the future of the printing industry and contribute to its advancement.

-

Manager working in a smart factory. In a smart factory with a central control room, the status automatically sent from equipment connected to KP-Connect Pro is displayed on the monitor, enabling real-time information to be obtained from the central contro

-

The newly established central control room is in the center of the photo. On the same floor, there is an open space that promotes free communication in a spacious environment as well as a production area equipped with printing presses and processing machi

-

The open space provides a calm, relaxing and open environment that promotes free and creative communication.