Komori held an open house, called Pre-IGAS 2018, on June 14 and 15, 2018 at the Komori Graphic Technology Center (KGC) located in Komori Corporation's Tsukuba Plant. The open house was held in the morning and afternoon on both days with 173 attendees from 86 companies.

To start, a seminar was held in the Tsukuba Plant Conference Room. Senior Operating Officer and Domestic Sales Group General Manager Yoshinobu Komori firstly gave a speech about areas Komori is developing--digitalization, automation, and intelligence--to tackle production issues facing printing companies, and the machines on display at this special viewing. Next, PESP Business Promotion Department General Manager and Domestic Sales Group Deputy General Manager, Yosuke Fujimaki gave a presentation with the theme, "Komori Product Development and IGAS 2018". The presentation introduced job management, automation, and quality control solutions that Komori is proposing to solve issues that Japanese manufacturing and printing companies are facing, namely individualistic production management, fragmented processes, and quality control through experience and feeling. After the seminar, demonstrations were given at KGC.

■Demonstration 1

Production matter

・500 sheets of a cosmetics catalogs

Demonstration machine

・Lithrone G37P (GL-837P)

H-UV L (LED)-equipped eight-color 37-inch convertible perfecting offset printing press (new product)

The new Lithrone G37P perfecting mechanism has a rotating structure at the gripper that is gripping the tail edge of the sheet, and there are no gripper changes while perfecting, enabling stable front/back register precision. In addition, smearing and scratches caused by the rim unique to the perfecting cylinder are eliminated since the surface of the perfecting cylinder is flat, and high print quality can be achieved.

In the demonstration, the Lithrone G37P automatically linked to KP-Connect Pro to receive the preset job data and printed a 16-page, A4 cosmetics catalog. The quality inspection device PQA-S V5, which is equipped with a sheet numbering system, maintains print quality and improves traceability during production printing. The audience saw one-pass printing at a maximum speed of 15,000 sph with the H-UV L (LED) curing system.

■Demonstration 2

Production matter

・300 sheets of gang-run printing

・700 sheets of a 16-page, A4 pet shop catalog

・300 sheets of a 16-page, A4 fashion magazine

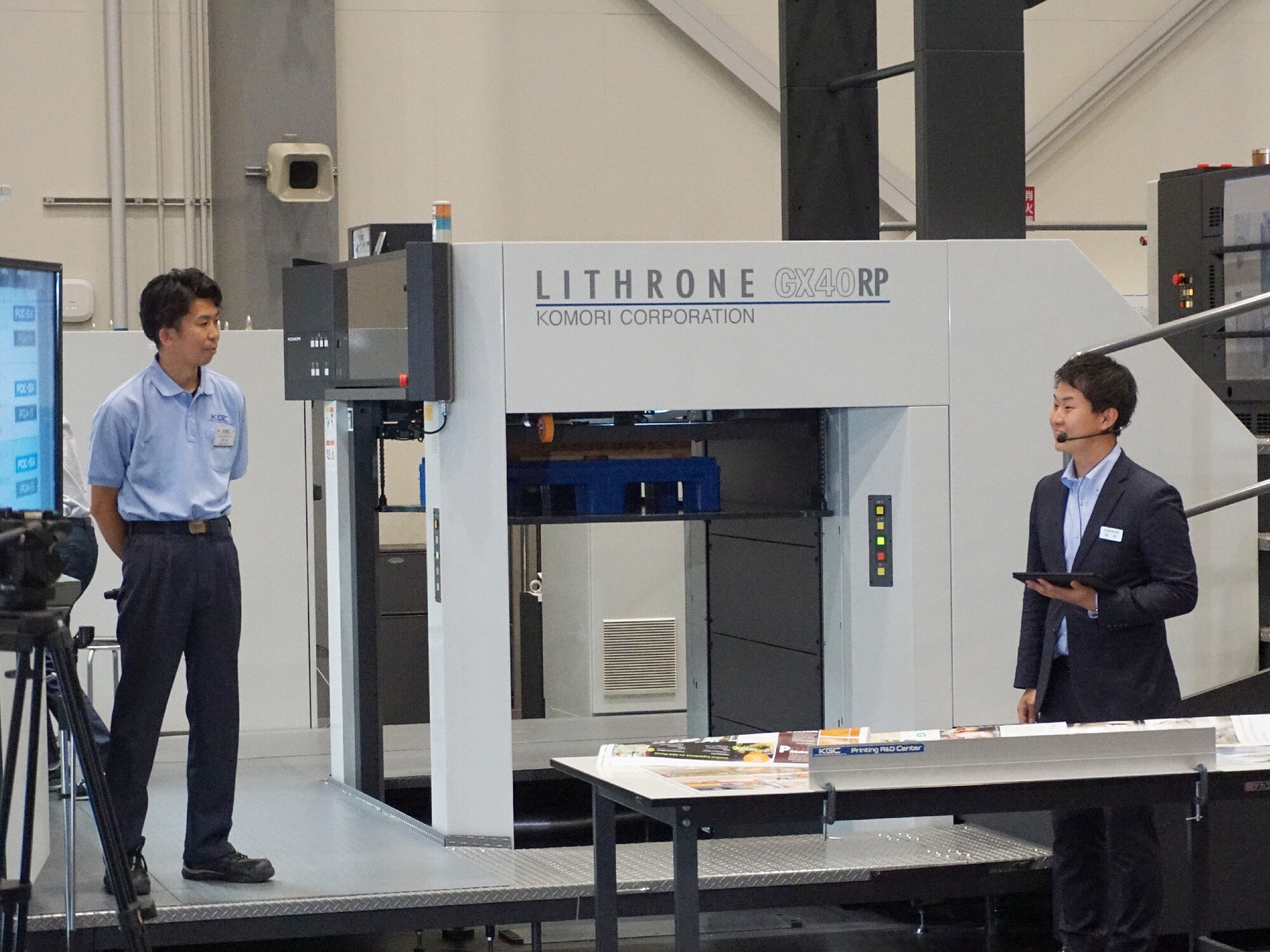

Demonstration machine

・Lithrone GX40RP (GLX-840RP)

H-UV L (LED)-equipped eight-color 40-inch front/reverse multi-color offset printing press

The Lithrone GX40RP, which makes stable one-pass, two-sided printing possible for a wide range of paper thicknesses, demonstrated Autopilot that prints three jobs nonstop with a single operator using preset data from KP-Connect Pro.

The first job began production printing at a top speed of 18,000 sph soon after the printing press started up and the audience saw the performance of the PQA-S V5 Print Quality Assessment System and H-UV L (LED). At job changeover, Parallel Makeready, which greatly reduces operator workload, came to the fore changing the plates with the A-APC Asynchronous Automatic Plate Changer, and performing blanket washing and ink settings all at the same time, enabling the three-job demonstration to be completed in 9 minutes and 49 seconds.

■Demonstration 3

Production matter

・300 sheets of 16-up postcard impositionsDemonstration machine

・Lithrone G29 (GL-629+C)

H-UV-equipped 29-inch offset printing press with in-line coater

With a maximum printing speed of 16,500 sph and superb high-speed stability even on heavy stock, the Lithrone G29 printed postcards with a drip-off effect that used a 4C process, OP varnish and coating by using preset data from KP-Connect Pro. In test printing, the PDC-SX Spectral Print Density Control automatically adjusted the color and register, cutting paper waste prior to production printing even for packaging printing that uses expensive paper. We introduced standard Komori K-Supply ink to meet a wide variety of needs from packaging special colors to coating, which was also used in the demonstration, and ink fountain film that decreases operator workload as well as reduces fountain cleaning time when changing colors required for packaging printing.

■Demonstration 4

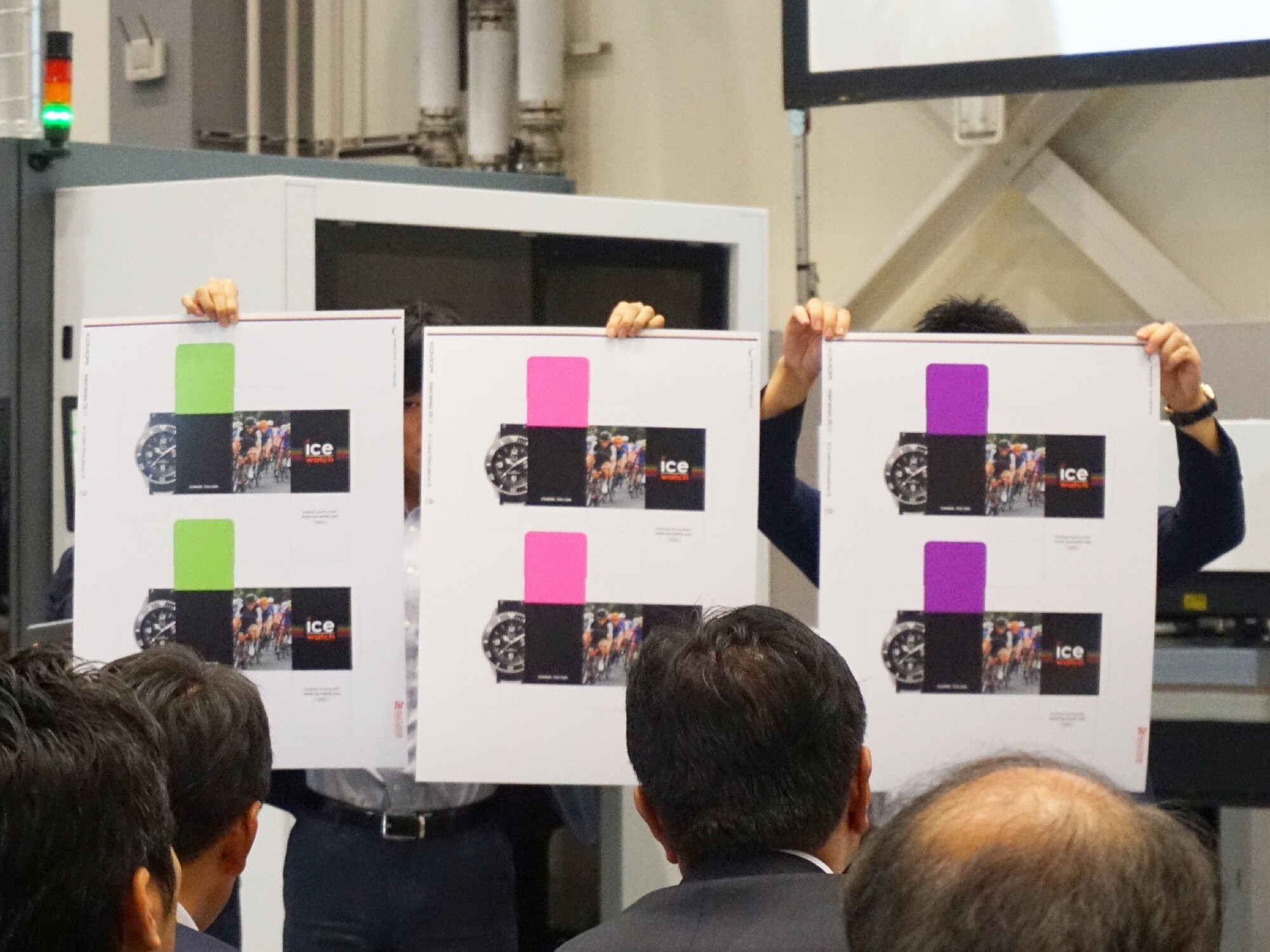

Production matter

・Photo book

・Watch packaging

Demonstration machine

・Impremia IS29 29-inch sheetfed UV inkjet digital printing system

・Highcon Euclid digital cutting and creasing system

The Impremia IS29 digital printing machine can print a variety of items and achieves short run and turnarounds as it is suitable for a wide range of paper, does not require special paper or pre-coating and can perform postpress immediately after two-sided printing with a high register accuracy thanks to the UV curing device. In the same way as an offset press, it received the preset data from the KP-Connect Pro. It then variably output the first job of a photo book with a wide range of RGB colors in book block format and the second job of watch packaging that used four special colors including colors for offset printing color matching. We also played videos from Fukuhaku Sogo Printing Co. in Fukuoka and Kosaido Co. in Tokyo that use the Impremia IS29.

Finally, we used the Highcon Euclid digital cutting and creasing system, of which 55 have been delivered worldwide, to score and minutely laser process the watch packaging. The audience was shown a sample.

After the demonstrations, we held mini-seminars about KP-Connect and K-Supply. The open house was a success with much passionate dialog and questions at the seminars about the machines.

We would like to thank everyone who attended the open house.

From printing presses and consumables like K-Supply ink to services, Komori Solution Cloud KP-Connect, and the postpress Apressia Series, Komori always provides next generation products designed with our customers in mind. We will continue to offer total printing systems that solve customer issues like cost cutting, improve productivity, and are high added value. At IGAS 2018, which is to be held at the Tokyo Big Site from July 26, we will exhibit a variety of solutions with the theme INNOVATE TO CREATE at the largest exhibitor booth. We look forward to seeing you there.