Approver : Ministry of Commerce of the People's Republic of China

Sponsors : Printing and Printing Equipment Industries Association of China, The Printing and Replicating Industrial Association of Guangdong, China International Exhibition Center Group Corporation

Venue : Guangdong Modern International Exhibition Center (Dongguan / Guangdong Province / China)

Scale : Exhibition area...about 140,000 square meters

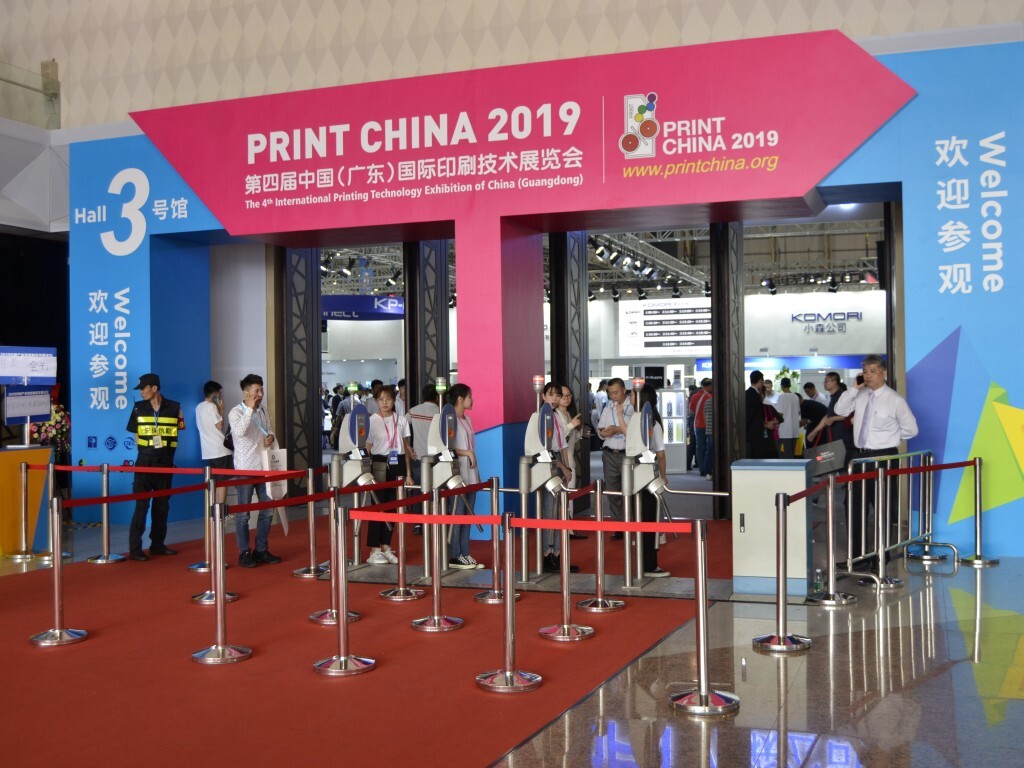

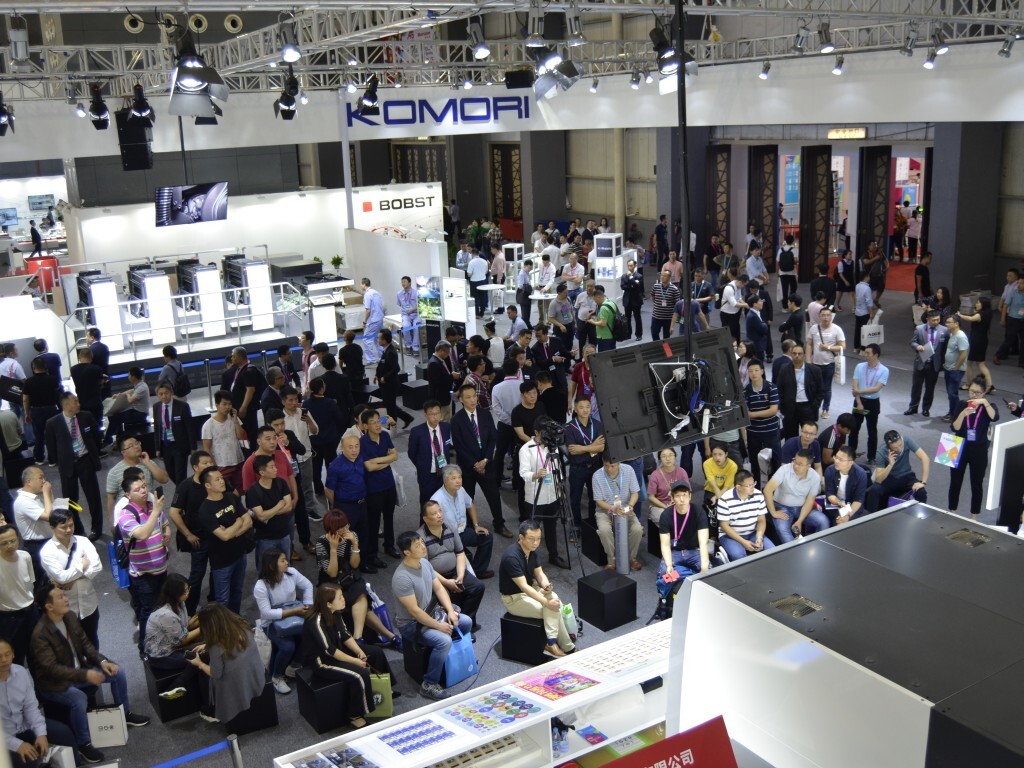

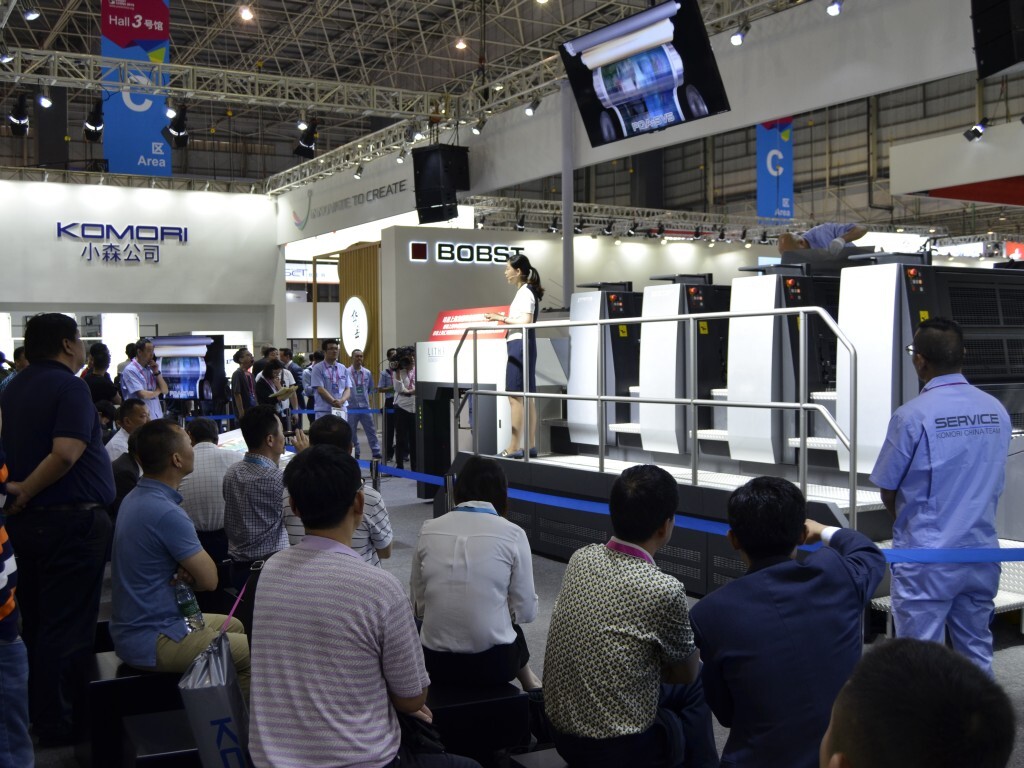

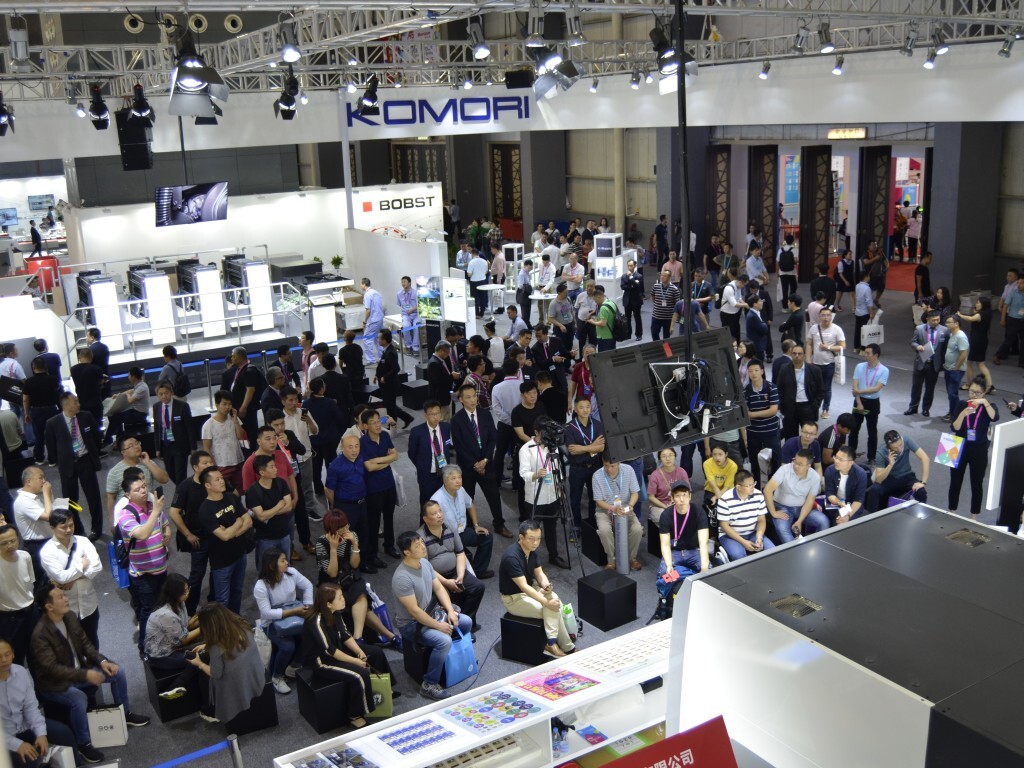

Print China 2019 - the forth International Printing Technology Exhibition of China was held for five days, from Tuesday, April 9 to Saturday, April 13, 2019 in Dongguan, China. According to the organizer's announcement, about 200,000 visitors came to the show for five days.

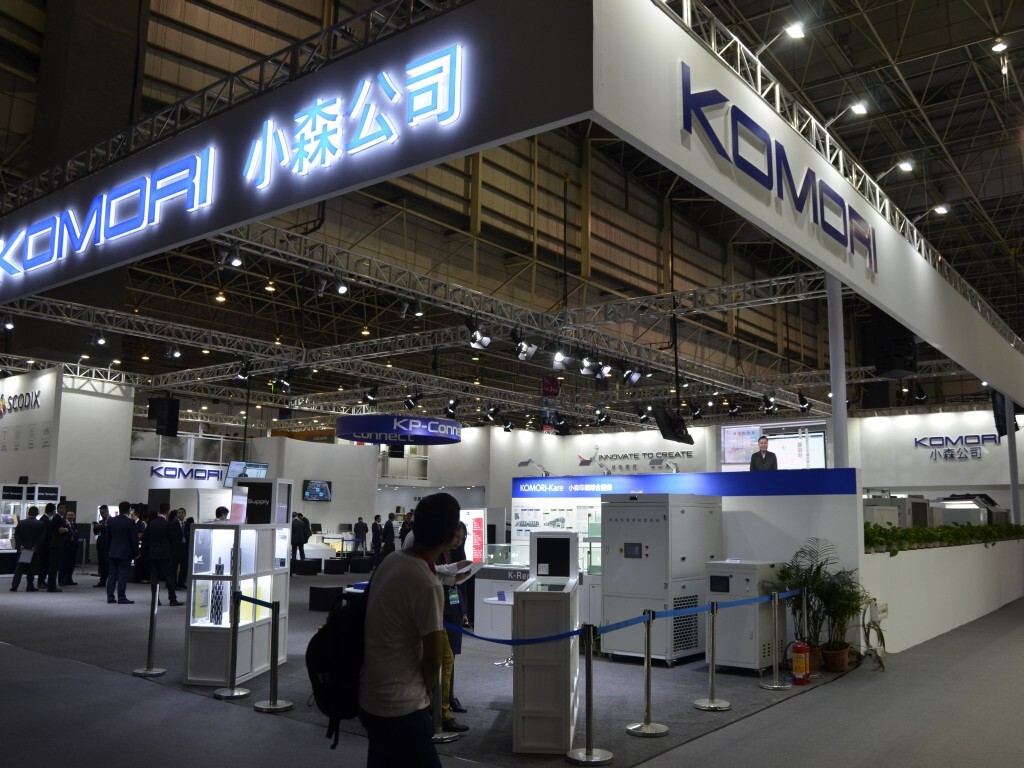

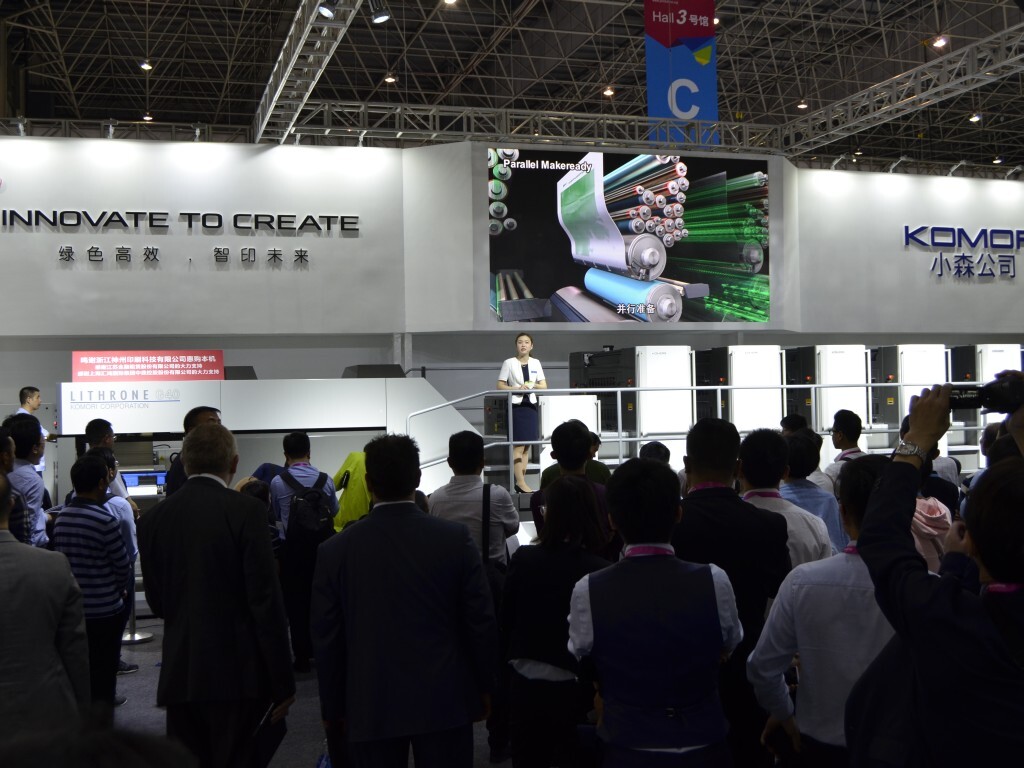

Komori exhibited under the theme "Innovate to Create" and introduced various useful solutions for printing companies with KP-Connect Pro (Komori Solution Cloud) at its core by all products such as offset, digital, printing materials and auxiliary equipment through demonstrations. From 'how to make' to 'what to create.' Komori intends to promote in partnership with printing companies innovation that shifts people from manufacturing to creating added value.

【Exhibit】

KP-Connect Pro : Komori Solution Cloud

Lithrone G40 : H-UV / H-UV L (LED)-equipped Seven-color 40"Offset Printing Press with In-line Coater (GL-740+Coater)

Lithrone G37 : H-UV L (LED)-equipped Four-color 37"Offset Printing Press (GL-437)

Impremia IS29 : 29"Sheetfed UV Inkjet Digital Printing System

■Demonstration

Komori wants to produce new creations with three technological innovations that are vital to manufacturing: digitalization and automation as well as intelligence, that is, accumulated printing technology of the printing industry. All the production machines were connected and completely managed, and the concept of product development was expressed with the theme of Smart Factory.

■Demonstration 1

【Demonstration machine】

・Lithrone G40 : H-UV L (LED)-equipped Seven-color 40"Offset Printing Press with In-line Coater (GL-740+Coater)

【Products】

1 : Wine Package (coated board 4C+ special color + gloss varnish)

2 : Wine Package (coated board 4C+ special color + OP varnish [drip-off effect])

3 : Wine Package (metalized paper white + 4C+ special color + OP varnish [drip-off effect])

So far, packaging solutions of the Lithrone series were installed in many packaging companies not only in China but also all over the world. Beginning of the demonstration, we introduced various machine specifications such as the unit for pre-coating, multi-color printing, drying and double coater to meet customers' packaging job. We also showed the video of the nine-color Lithrone G44 with double coater and double delivery carried in HungHing in Guangdong.

Then, job data for the Lithrone G40 was sent from KP-Connect Pro. The Lithrone G40 printed the wine package at the maximum speed on 0.45 mm coated board with 4C process ink, one special color and gloss varnish. The second job expressed high-value added drip-off effect using OP varnish (drip-off effect) and gloss varnish. For the third job, it printed on metalized paper white color at first, OP varnish (drip-off effect) and gloss varnish. This job showed that high-value added printing with in-line coater can expand the opportunity of packaging job.We also showed high curing ability on special paper by H-UV L (LED).

《Product information》

Lithrone G40

https://www.komori.com/en/global/product/press/offset/lith-g/g40/

Lithrone GX40

https://www.komori.com/en/global/product/press/offset/lith-gx/gx40/

■Demonstration 2

【Demonstration machine】

Lithrone G37 : H-UV L (LED)-equipped Four-color 37″Offset Printing Press (GL-437)

【Product】

1 : Postcard (cardboard)

2 : A4 advertising flyer (matte coated paper)

3 : A3 poster (special paper : YUPO)

The Lithrone G37 has the power to address the full span of requirements on both light and heavy stocks as the A1 size press that's compact and yet handles full-size work. The Lithrone G37 has an edge over competitors in terms of a 16-page A4 paper size with the color bar. In addition, the five-color Lithrone G37 can be installed in the same space with four-color 40-inch press due to its compact size. There is a record that the plate cost could be reduced by twenty million yen at a printing company because the Lithrone G37 can use smaller plate than usual 40-inch press.

In the demonstration, receiving the preset data automatically from KP-Connect Pro, the Lithrone G37 printed 6-up post cards on cardboard for the first job. After the production printing at the maximum printing speed of 15,000 sph, the Lithrone G37 equipped with the H-UV curing system and Full-APC (automatic plate changer) finished the blanket cleaning, automatic plate change and pre-inking. Then, the Lithrone G37 printed 4-up A4 flyers on matte coated paper for the second job.

After the additional changeover, A3 posters were printed on the YUPO, special paper for the third job. After the demonstration, we also introduced the video about our various solutions for commercial printing.

《Product information》

Lithrone G37

https://www.komori.com/en/global/product/press/offset/lith-g/g37/

■Demonstration 3

【Demonstration machine】

Impremia IS29 29"Sheetfed UV Inkjet Digital Printing System

【Product】

1 : Clothing tag (YUPO 4C/4C)

2 : Greeting card (Textured paper 4C/4C)

3 : Photo book (matte coated paper 4C/4C A4x4)

The Impremia IS29 is suitable for printing on paper with wide range of thickness and size, and capable of both single-sided and double-sided printings. It does not need certified paper and even more it can print on the same paper as offset without any pre-coating or special pre-treatment. The machine achieves high-mix low volume production by highly accurate registration with gripper sheet transfer technology which is same as our offset printing machines, and quick transfer to the post-press process by instant UV curing and double-sided printing in one pass.

In the demonstration, the Impremia IS29 received the preset data for the jobs from KP-Connect Pro. For the first job, the Impremia IS29 printed 4 kinds of tags on P/P YUPO sheets with reproduced special colors using 4 colors of Impremia IS29 inks. The Impremia IS29 can indeed cover 80% of Pantone colors with the CMYK inks. The Impremia IS29 can achieve significantly stable color density. IS29 can produce stable color within a sheet (such as right top and left bottom of the sheet) and also between sheets (such as 1st sheet and 1,000th sheet.)If the customer has repeated job after a month, they can print the job with the same color without adjustment.

For the second job, variable greeting cards with different numbers on every sheet were output. It also proved the high print quality that the Impremia IS29 can evenly print on textured paper without white spots. We showed print samples on Japanese traditional paper "washi" and visitors could see how Impremia IS29 has high compatibility on printing on special substrates as well.

For the third job, the Impremia IS29 output the photo book on matte coated paper in single-sided printing at the maximum printing speed of 3,000 sph. We introduced Komori's color matching system "K-ColorSimulator2" and showed color matching with offset at very high accuracy with easy and simple operation.

In addition, we showed a interview video of Artorn who already has 25 sets of Komori's offset machines. They explained how they utilize their 2 sets of IS29 for their new business.

《Product information》

Impremia IS29

https://www.komori.com/en/global/product/press/digital/is29/

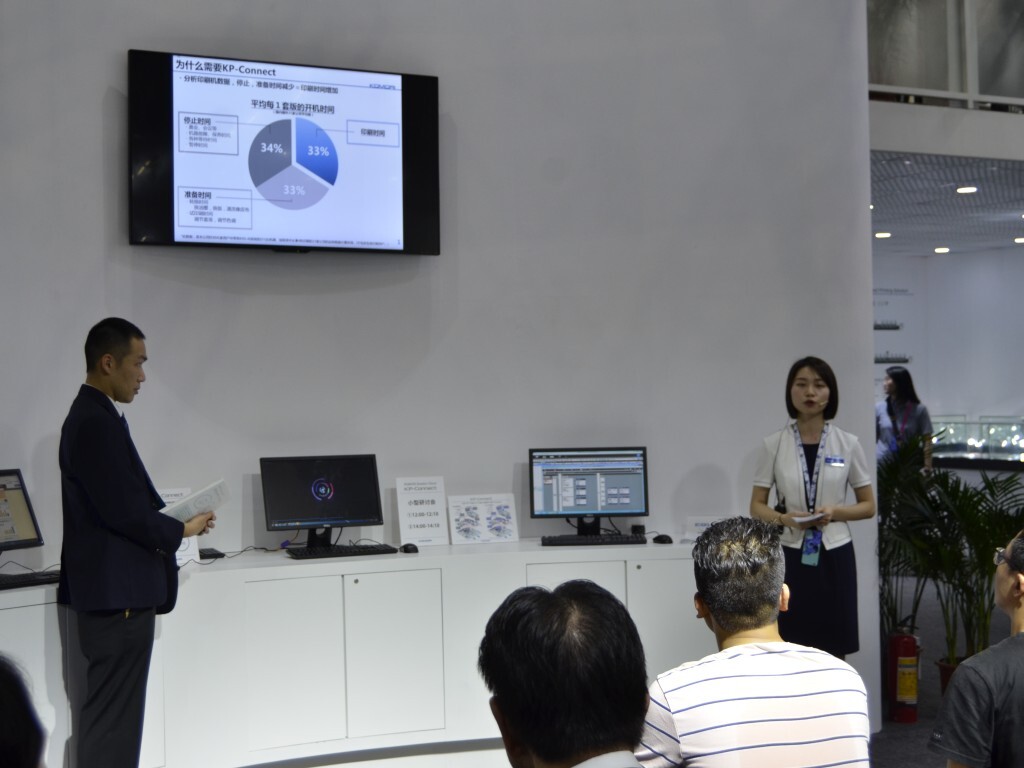

【KP-Connect coner】

KP-Connect Basic is a service that improves productivity by allowing the printing company and Komori to share detailed press operating information in the secure environment of the cloud, making printing operations visible in real time. KP-Connect Pro digitizes and streamlines process management by means of the MIS linkage function and scheduler. In addition, it realizes overall optimization of the printing process by workflow automation with prepress and postpress. In the Komori stand, how problems at the printing factory can be solved by implementation of KP-Connect was introduced with a video. Also, in the ICT Solution corner, a lot of visitors experienced the demonstrations of KP-Connect.

《Product information》

KP-Connect

https://www.komori.com/en/global/product/press/kp-connect/

【KOMORI-Kare Corner】

Under the K-Supply brand name, Komori offers a lineup of special consumables, materials and equipment that are standard for Komori-made presses. K-Supply is not just consumables but also printing supplies developed with the Komori Graphic Technology Center (KGC) for high print quality and performance. All exhibit presses used K-Supply, and products such as K-Supply ink, dampening solution and blankets are standard Komori materials offering high-level print quality, versatility and economical performance ideal for H-UV printing.

《Product information》

https://www.komori.com/en/global/support/komorikare/

【Print Gallery】

In the Print Gallery, samples of package and added value printing using unique technology such as 3D lenticular from all over of the world were displayed, and the technique and cases of use were introduced. The currency/security press corner was set up in the print gallery. The widely-used anticounterfeiting technologies and samples of Komori currency/security presses were introduced in panels.

From printing presses and consumables like K-Supply ink to services, Komori Solution Cloud KP-Connect, and the postpress Apressia Series, Komori always provides next generation products designed with our customers in mind. We will continue to offer total printing systems that solve customer issues like cost cutting, improve productivity, and are high added value.