Lithrone G40 advance increases efficiency of high-quality art printing by 30 percent

China, Artron Art Group | Lithrone G40 advance [GL-540A]

10 December 2021

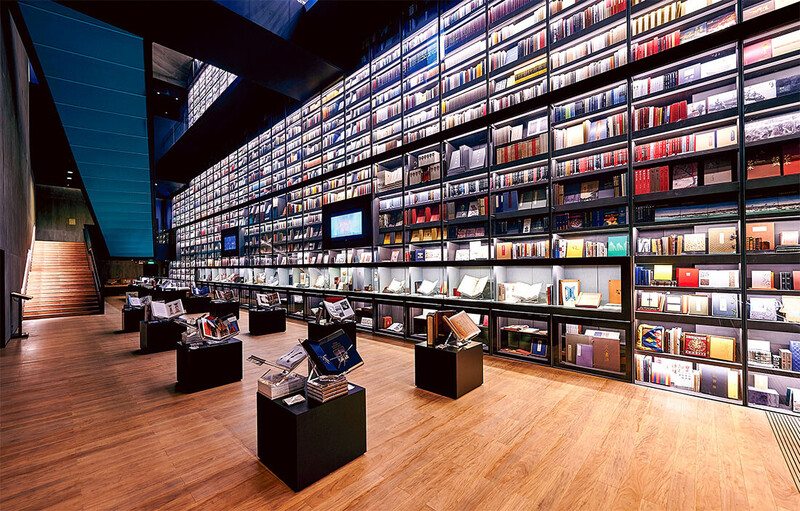

Founded in 1993, the Artron Art Group has made a name for itself around the world as an integrated company committed to the enterprise of culture. Artron's mission is to "serve the people with art by serving the people's art." By integrating a range of technologies, Artron has become one of the world's top cultural and art-related service providers, conveying the beauty of art to the world.

Artron Shanghai was established in 2006 and is their third integrated operation base in China after Shenzhen and Beijing. In 2013, the company moved their headquarters to the Jiading District of Shanghai, and their industrial park now has a very rich artistic atmosphere and covers an area of 22,000 square meters. Artron's policy throughout is to serve companies in the fields of high-quality art, fine art, art auctions, and luxury brand products as well as prestigious businesses, and such firms now make up their main customer base.

Artron: leader in fine art printing

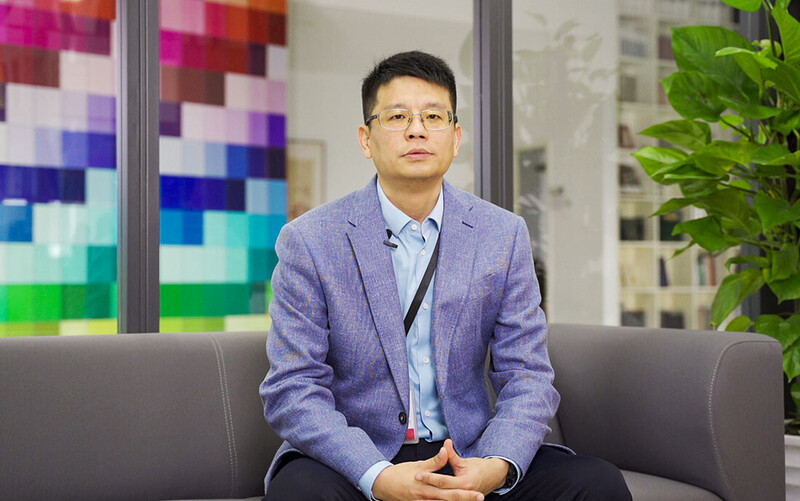

Zhang Yao-kang, Executive Vice President of Artron Shanghai

Zhang Yao-kang, Executive Vice President of Artron Shanghai, says, "We have been using Komori presses since our founding. The first were the Lithrone 40 series presses, followed by the Lithrone S40 and the Lithrone G40 series, and now the Lithrone G40 advance series press introduced this year. The Shanghai plant is now running a total of eight Komori presses. The main reason for the introduction of the five-color Lithrone G40 advance press with coater is that we are printing "The Collection of Chinese Historical Paintings." This very important art book published by Zhejiang University Press collects the best paintings of Chinese dynasties from the Qin Dynasty to the Qing Dynasty and has been designated a national publication fund project.

The collection demands a very high degree of integrity and requires the use of 280-line high-definition screen printing and very sophisticated reproduction of the original paintings. Therefore, the specifications for printing and binding quality are extremely strict and the constraints are very high. In addition, the customer is also making demands regarding the performance, condition, and operating life of the printing presses. Against this background, we proactively contacted Komori and they overcame a number of difficulties amidst the Covid-19 pandemic, arranged a variety of resources, and installed the advance machine for us in July 2021. The timing of the press installation was very good, and it saved us a lot of trouble."

Lithrone G40 advance increases high-definition printing efficiency by 30 percent

Commenting on the effects of the new press, Vice President Zhang Yao-kang says, "The introduction of the new press has greatly helped to improve our overall efficiency, which has increased by 30 percent. In the past, we were limited to five or six jobs per shift, but now we can print up to eight jobs. We also feel that the advance model has significantly improved feeder and delivery performance, and the overall stability of the press's operation has been significantly improved. This goes a long way in ensuring our overall productivity and efficiency.

In addition, when printing with the state-of-the-art Lithrone G40 advance, dot and color reproduction is excellent, and our customer is very satisfied with the print quality of the finished product for our most important project, "The Collection of Chinese Historical Paintings."

The ultra-high-definition color reproduction by Artron, an enterprise synonymous with high quality printing, can only be achieved by using the most advanced printing machines. The performance of the press in the printing process plays a crucial role in reproducing the originals. Technology such as the unique Komorimatic continuous dampener on the Lithone G40 advance model maintains the minimum water supply required and provides a more stable supply of dampening solution. By reducing UV ink smearing and maximizing the benefits of the Komori dampening system, the press achieves even faster color reproduction and more reliable color management. This kind of subtle differentiation and design, which is not easily captured, has resulted in the sharp halftone dot reproduction of Komori presses and has contributed significantly to Artron winning numerous printing awards.

Lithrone G40 advance more convenient and intuitive

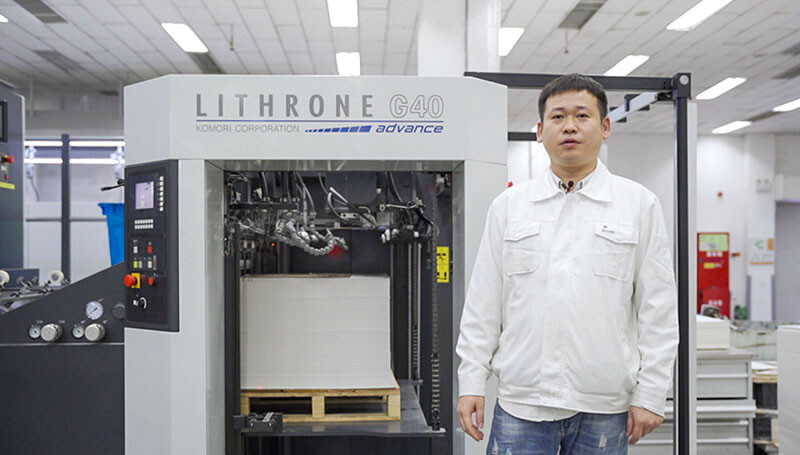

Liu Lei, Printing Manager

This overall increase in efficiency is closely related to the wide range of performance improvements that the advance series press brings to the table. Liu Lei, a printing manager who has operated different series of Komori presses, commented on a number of improvements in the new model. "With the feeder, the operator used to manually stack the paper and align it with the center point. Now we can track it automatically with the monitoring sensors on both sides and with automatic adjustment to the proper pile position, which is even more convenient. For the delivery, the number of suction wheels has been increased on the latest model, enabling more stable and neater paper delivery even at high printing speeds."

The printing speed specification of this model is for the Chinese market.

"The operation screen of the PQC Print Quality Control System is more intuitive than ever, allowing us to visually check the current and preset values of each ink application quantity, and to control the increase and decrease of ink supply. Another major improvement is the checking of the ink distributing roller. In the past, it was necessary to climb up the steps of the machine, open the safety cover, and check the ink distributing roller by loosening the screws, but now it can be checked simply by touching the screen, reducing maintenance time. Also, for replacing the blanket, when attaching or detaching the blanket cylinder gap cover, damage to the press resulted if the plate was misaligned. Now we use a fixed gap cover, which reduces manual operation and significantly reduces the safety risk. By simply scanning the color bar with the PDC Print Density Control System scanner, the density and Lab values are neatly displayed on the screen, and with the P4 pre-inking function, the balance between the dampening solution and ink quickly reaches an OK level, leading to reduced paper loss."

Artron and Komori: a strategic partnership

Artron and Komori first met 25 years ago in 1996. Commenting on the partnership between Artron and Komori over the years, Vice President Zhang Yao-kang says, "As Artron has grown, we have also witnessed the expansion of Komori's business in the Chinese market. Moreover, Komori has played a very important role in our growth process, providing us not only with the indispensable printing presses but also a great deal of support, including technical cooperation, establishing printing standards, and training. Several years ago, Artron and Komori collaborated on a project called "Chomolungma Action." Specifically, we invited experts from Komori's technical and production fields to help us improve Artron's overall management of production technology, printing site management, and efficiency, and this was very helpful."

Zhang describes the collaboration between Artron and Komori: "In the past few years, Komori has also started sales of digital printing systems. Artron Beijing has already installed two Komori Impremia IS29 digital printing systems, and we are planning to install a Komori Impremia NS40 digital printing system using nanotechnology in the spring of 2022. In the future, Artron and Komori will have more opportunities to collaborate. I think there are better opportunities for both companies, not only in the area of production equipment but also in exploring business models. And we hope that Komori will develop many more superb machines and provide us with more technical assistance and support."

In 2022, four Lithrone G40 advance presses will be newly installed to contribute to Artron's art business.