Red & Blue Printing Brightens the World with Colorful Printed Products

New Taipei City, Red & Blue Printing Co., Ltd.

13 October 2023

Founded in 1965, Red & Blue Printing Co., Ltd., with over half a century of printing experience, primarily serves the high-quality commercial printing needs in the Zhonghe District of New Taipei City. Its main print products are catalogs, albums, and packaging for well-known brands. With the changing landscape of society and economics and the rise of digital printing technology, commercial printing work is gradually transitioning to digital printing. As Red & Blue Printing approaches its first year in a new plant, it aims to ride the wave of this transformation. In addition to its core competency in commercial printing, the company plans to take on the challenge of package printing, leveraging its years of professional experience to carve out new horizons in the packaging industry.

Chen Chao Hsiung, CEO

One-stop and customized services

In the competitive printing market, Red & Blue Printing actively promotes innovation. It not only incorporated a package printing line into its main production but also constructed a new plant in Yangmei District, Taoyuan City in 2019, officially commencing operation in August 2022. The new plant not only alleviates the congested conditions at the Zhonghe plant but also extends its diverse service range. To comply with ISO 22000 food safety management requirements, Red & Blue Printing meticulously planned the facility as an energy-efficient, carbon-reducing, and food-safe plant, providing a full range of customized services. The three key features of its services are as follows:

1. One-Stop Service: From design to prepress, printing, postpress processing (varnishing, laminating, foil stamping, hot stamping, punching, window pasting, folding, gluing, saddle stitching, and manual assembly), and logistics.

2. High Reproducibility: G7 color management, professional high-definition screen printing, and color correction to optimize dedicated image retouching service.

3. Environmentally Friendly Manufacturing Process: FSC certification, soy ink printing, alcohol-free printing, eco-friendly plates, eco-friendly decontamination, solar power generation, and other advanced equipment and technologies.

Established nearly 60 years ago, Red & Blue Printing has long been committed to creating value for its customers and has provided services to numerous clients, including the National Palace Museum, Mercedes-Benz Taiwan, Dentsu Taiwan, Samsung Taiwan, Taiwan Power, China Airlines, Uniqlo Taiwan, DNP (Japan), KiwiCo (USA), and others.

Supported by many outstanding clients, the company produces a wide range of printed products, including books, magazines, photo albums, calendars, catalogs, notepads, packaging, and cards. Red & Blue Printing has received numerous printing awards, including the Premier Print (Benny) Award from the United States, the highest honor in the world's most prestigious international print competition, the Sappi Award, and Taiwan's Golden Print Award. Alongside other gold award recipients, the company is honored to contribute to further improving the quality of printing.

Facility upgrades and efficiency improvements

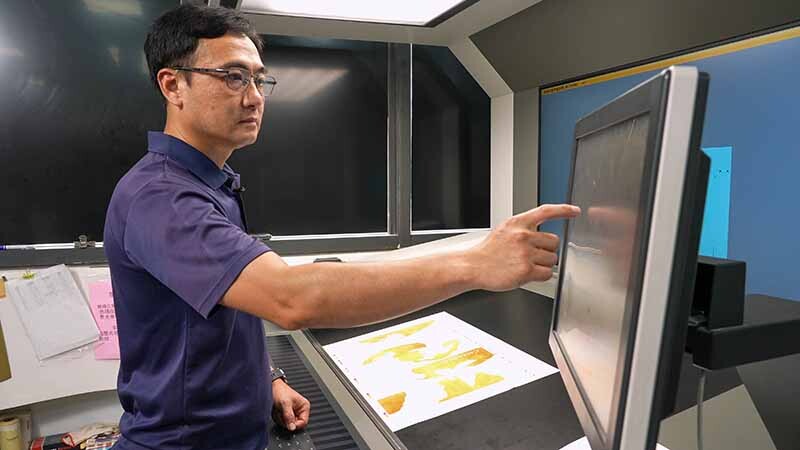

With the advent of the digital transformation era, Red & Blue Printing, as a result of many assessments, chose the Komori press as its partner for the transformation of the packaging printing market at the Yangmei plant. The innovative and automated features of the press along with corresponding to the company's needs were the primary reasons for this choice. Furthermore, the press offers stable performance and easy, quick maintenance. CEO Chen Chao Hsiung noted, "I personally appreciate many functions of the 6-color Lithrone G40 advance UV press. The most important is its PQA-S monitoring system, which guarantees quality."

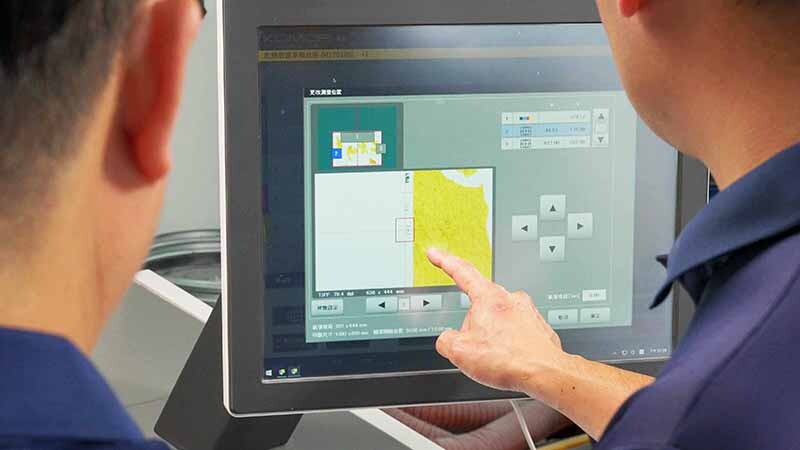

While Red & Blue Printing has used other manufacturers' presses for many years, it first considered adopting Komori machines after noticing them being installed by other printing companies. This is the first time Red & Blue Printing has introduced a Komori press, but the operators received training from Komori service staff and mastered the high-level functions of the Lithrone G40 advance. As functions that support printing, KHS-AI significantly shortens plate-changing times, while PDC-SX and PQA-S contribute to achieving print quality control. The ink rollers are designed to be easily taken apart and reassembled, ensuring swift, precise adjustment. The Human Interface Device offers an easy-to-use intuitive display for operators. With the powerful performance of the highly automated Komori press, the company's productivity has improved by more than 30%.

Those who most appreciate the high performance of the Komori press are the operators. On the day of the interview, Hsu Yu-Li, the printing press operator, printed a 650g/m2 job at 13,000 sph, stating enthusiastically, "We are printing 5,000 sph faster than with conventional presses, but the speed is stable and there is no print blurring. It's truly an excellent press." He adds, "We expected the 6-color Lithrone G40 advance UV press to meet and even exceed customer quality requirements. In reality, the Komori press guarantees the quality that customers demand, and we are satisfied with its productivity and print quality. Additionally, when customers visit our company, they are amazed by the press's stylish appearance and the large KID display that provides multifunctional printing information. For example, KID can show enlarged dots, enabling instant communication with customers and offering the sense of a different printing experience. We confirmed that the new press meets our requirements, and now all products developed at the Yangmei plant, including food packaging, pharmaceuticals packaging, cosmetics, and export orders, are printed on the Komori press."

Social responsibility and environmental sustainability

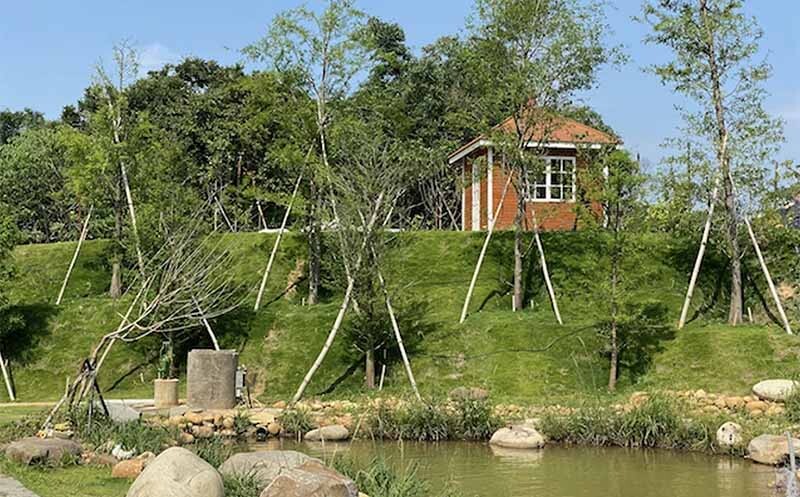

To transform the Yangmei plant into an energy-efficient, low carbon dioxide-emitting, and food-safe facility, Red & Blue Printing obtained ISO 22000 food safety management. The company also installed a solar power generating system and eco-friendly processing equipment in the plant, and an ecological park is set behind the plant. The newly introduced Lithrone G40 advance is designed for energy efficiency and carbon dioxide emissions reduction. "We have tried our best to be environmentally friendly and sustainable, allowing the entire plant to achieve more than 40% energy savings and reduced carbon dioxide," says plant manager Tseng Chih Cheng. Red & Blue Printing places a strong emphasis on energy-efficient and carbon dioxide-reducing facilities such as:

Tseng Chih Cheng, Plant Manager

1. Solar Power Generation System

Installed 634 solar panels in the plant, capable of generating approximately 212,000 kWh of electricity annually, leading to an annual reduction of 111 tons of carbon dioxide emissions.

2. Environmentally Friendly CTP Direct Production Press

Not only space-efficient but also with low running costs for water and electricity.

3. 6-color Lithrone G40 advance UV Press with PQA-S Print Quality Assessment System

Automation devices, including Full-APC automatic platechanger, KHS-AI, PDC-SX Spectral Print Density Control, and PQA-S Print Quality Assessment System, enhancing productivity and quality throughout the printing process. The press also reduces the volatile organic compounds (VOCs) emitted during the printing process, complies with RoHS requirements, and reduces machine noise levels, minimizing the environmental impact of the printing process and protecting the natural environment.

4. Air Conditioning System Distributed Duct System

Compared to conventional ducts, the system provides better air conditioning uniformity, reducing the initial plant air conditioning demand from 60 tons to 30 tons, which is sufficient for needs. The outdoor air conditioning units adopt an air-cooled cooling system, eliminating the need for water for heat dissipation and thus saving water consumption.

5. Other Low-Power, Energy-Efficient Systems

Plant hall lighting control system, RO reverse osmosis membrane electrical control, printing area exhaust system, and maintenance of plant greenery.

Ecological park

Creating a win-win through professionalism and enthusiasm

In the future, Red & Blue Printing will inherit the achievements it has nurtured and align with the company's vision of "striving to become an innovative enterprise and making printing applications advance with the times," so the company will continue to enhance its printing technology and provide services that customers trust. To ensure service quality for customers and offer a more diverse range of printing services, Red & Blue Printing has obtained certifications such as ISO 22000 Food Safety Management, ISO 9001 Quality Management, ISO 14001 Environmental Protection Management, SA 8000 Social Accountability, Forest Stewardship Council Chain-of-Custody Certification, and G7 Color Management. The company plans to further its development in areas such as (1) process and quality improvement, (2) diverse technological research, (3) innovative product development, (4) active expansion into overseas markets, and (5) environmentally conscientious sustainable management to achieve the mission of "promoting social progress and development through our enthusiasm and professionalism."

Finally, CEO Chen Chao Hsiung expresses his thoughts on the purchase of the Komori press and his gratitude to the Komori service team in Taiwan and assesses the flexible, quick support. "Komori has a history of over 20 years in Taiwan and has already established a strong presence in the Taiwan press market. Therefore, Red & Blue Printing expects Komori to continue to provide high-quality maintenance services, contributing to the sustainable and diversified development of Taiwan's printing industry. I also hope that Komori will advance to the next stage, creating a win-win situation with manufacturers and generating mutual benefits."