Komori starred at IGAS, taking over the Tokyo Big Sight exhibition center from September 11 to 16 and showing off products, technologies and ideas never before seen at a major printing exhibition. In fact, this was a hugely important presentation for the re-invented and evolving Komori. The digital side of the Komori lineup took a major step forward while a fuller range of postpress machinery debuted. And the PESP initiative was center stage and a part of all the demos. But over and above these solid achievements, the message of innovation and forward movement was unmistakable.

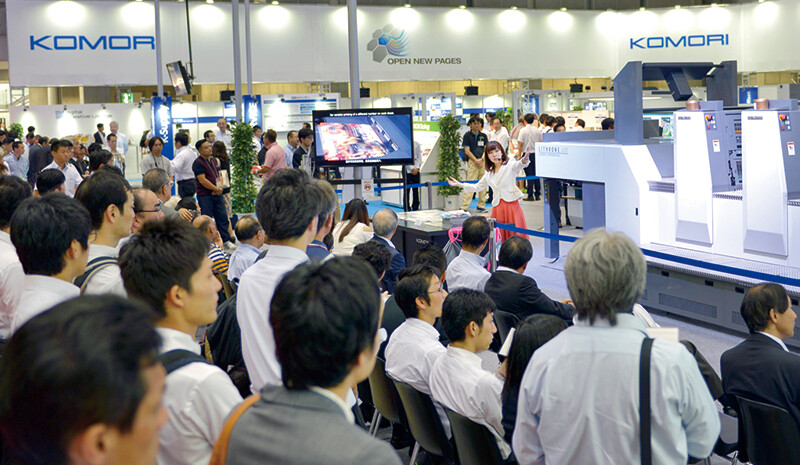

The Komori theme was 'Open New Pages,' and users gained input on exactly how to expand the new potential of printing and realize richer print communications. No longer just an offset press manufacturer, Komori produces digital printing systems, postpress hardware, printed electronics, and printing materials and equipment. The subtheme for the exhibition was 'Connect' — Komori's solutions for new value by linking products over the cloud and connecting with customers were tightly integrated into the demos.

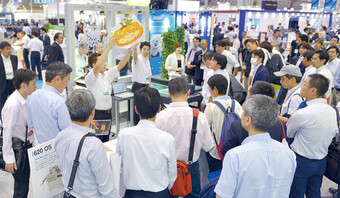

The Impremia IS29 digital printing system — emblematic of Komori opening new pages — was the highlight of the show, gathering an enthusiastic crowd every time the stirring demo began. The magic of connecting offset and digital filled imaginations and conversations.

H-UV offset presses on exhibit ranged from a four-color Lithrone A37 specified with multiple new color management and workflow solutions to the mighty eight-color Lithrone GX40RP configured with every option under the sun. The six-color Lithrone G40 H-UV in packaging specification was also displayed with many special systems designed for this application.

The new K-Station 4 for sharing the latest operating information and making complex printing task control visible. And a growing lineup of Apressia postpress equipment, including programmable hydraulic clamp cutters and a flatbed die cutting machine, to support business models that extend to the final product. Total solutions with state-of-the-art performance and Komori's legendary reliability. Everything necessary to open new pages.

Showstopper: Impremia IS29

The futuristic Impremia IS29 digital printing system was introduced by a science fiction-themed video perfectly attuned to the ultramodern looks of Komori's first UV sheetfed inkjet digital printing machine. The mission of the Impremia IS29 is to embody the performance that printers demand in a true digital solution. These are, first, the ability to print on ordinary offset printing paper. No special or precoated stock necessary. Second, high print quality with vibrant color. And third, the capability for both single-sided and double-sided printing with printed work ready for immediate postpress finishing. The IS29 was born in the pursuit of these capabilities.

The first job run on the IS29 was an example of versioning, as 15 sheets each of 6 different posters were printed on vent nouveau paper, a stock with rich texture that is often selected for added value work.

The presenter oriented the audience to the makeup of the new digital printing system, explaining that the printing unit is designed for stable sheet transport and incorporates a fully automatic gripper-to-gripper perfecting changeover mechanism. The triple-size cylinder in the center of the printing unit features inkjet heads above the cylinder and the LED-UV drying system set to the rear. Paper is printed from the first sheet — meaning no waste. The maximum printing speed is 3,000 sph single-sided and 1,500 sph double-sided.

K-ColorSimulator 2 was put through its paces, comparing a sheet from the Lithrone A37 and the same image from the IS29. The demo was then 'interrupted' by an urgent order that showed off the ability of K-Station 4 printing task control software to manage scheduling and production from a tablet using a very intuitive interface. Jobs were rescheduled by drag and drop, and all changes, including color management, were simultaneously mirrored and set in the IS29.

The operation of the IS29 was fascinating, but the results were mind-blowing. Stunning sharpness and a '3D-ish' feeling of depth. No question, the IS29 was the talk of the show.

Lithrone GX40RP | Lithrone G40 | Lithrone A37

Connect was the subtheme of the Komori booth at IGAS, and the offset press demos featured the most connected machines ever seen in the world of printing — connected to other machines, software and devices.

The mighty eight-color Lithrone GX40RP H-UV was the prime example. This press spotlighted connections to K-Supply printing materials and software, the K-Station 4 Printing Task Control System that connects all processes, the Apressia series postpress equipment that connects up to the final product, and the new KP-Connect support system.

This press ran two 4-over-4 jobs at 16,500 sph using K-Supply KG-911 H-UV Ink. The world's fastest changeover — driven with parallel control by Smart Sequence and asynchronous plate changing by A-APC — was shown on a timer. All processes were controlled by K-Station 4, which was mirrored on a tablet to make all scheduling, process and production data visible in real time. And KP-Connect gathered KHS-AI data uploaded to the cloud for use in maintenance and support, discovering problems and presenting solutions. Accessible, of course, to printing company executives from a tablet or smartphone.

The six-color Lithrone G40 H-UV with coater specified for package printing was paired in the demo with the new Apressia DC105 die cutter, Komori's first product solution for packaging. Print quality and color control options for packaging were also state of the art: first, the Sheet Numbering System that is linked to the PQA-S quality inspection system; and second, the PDC-SX Spectral Print Density Control equipped with the PDF Comparator System that compares the scanned sheet with prepress data. New technology also included an innovative ink mist removal device to maintain a clean plant environment.

The four-color Lithrone A37 H-UV was specified with a new PQA-S SG print quality inspection system and the new PDC-SG print density controller, and was linked to the Impremia C100 full color POD. Color matching between the offset and digital machines was handled by K-ColorSimulator 2, Komori's revolutionary easy-to-use CMS software.

So much more filled the presentations of the offset presses — Komori-Kare for kando in the pressroom, environmental options such as the power consumption monitor, and endless options for workflow automation and precision control of all printing parameters. No wonder the demonstrations were standing room only.

Komori Total Solutions

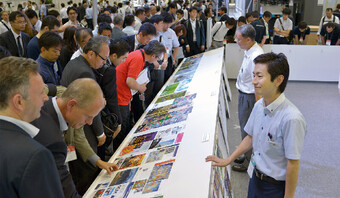

Ideas for opening new pages were everywhere in the Komori booth at IGAS 2015 — in new machines, in breakthrough software, in specially formulated materials and in the cloud. The demonstrations highlighted the major products, and considerable space was dedicated to showing the evolving equipment lineup.

The Apressia CT115/CT137 programmable hydraulic clamp cutters are Komori's first foray into the postpress arena. IGAS was also the stage to debut the new Apressia DC105 flatbed die cutting machine in the packaging zone. The digital Creative Lounge, transplanted from Komori's head office to the IGAS booth, exhibited the Impremia C100 digital printing system with K-ColorSimulator 2 as well as a laminator and cutting plotter as part of its range of digital solutions.

The software solutions exhibited will figure large in the calculations of Komori printers, especially K-Station 4, the tablet-ready integrated press management system that handles order, scheduling and production data. Positioned between the MIS and KHS-AI v. 5, this system directs the operations of digital and offset presses, including machines manufactured by other makers. K-ColorSimulator 2 is the offset-based color management solution for color matching offset and digital output. And an entirely new cloud-based support system called KP-Connect connects Komori to customers, facilitating online analysis of press operation and communicating recommended actions when problems are found. Managers can log on to KP-Connect with any PC, tablet or smartphone.

The PESP concept is broad, covering consumables like inks and blankets, as well as a wide range of upgrade and retrofit options, such as high-performance DC blowers and H-UV retrofit packages. As a service provider, Komori will address a wider spectrum of customer needs through products optimized to deliver maximum performance from Komori presses. And this approach will eliminate guesswork and take the stress out of everyday operations. Komori's total solutions are already being updated and fine-tuned for their next appearance: drupa 2016 in Düsseldorf, Germany.