Digital: Agent of Change — New Printing Opportunities with Digital Printing Systems

01 August 2017

Komori OnDemand: The combination of offset and digital. The Komori answer to changing print markets and the ever-evolving printing environment. New business models and a greater competitive edge. An interview with Shogo Kitabayashi, Group General Manager, DPS Sales Promotion Group, on the digital printing systems from Komori.

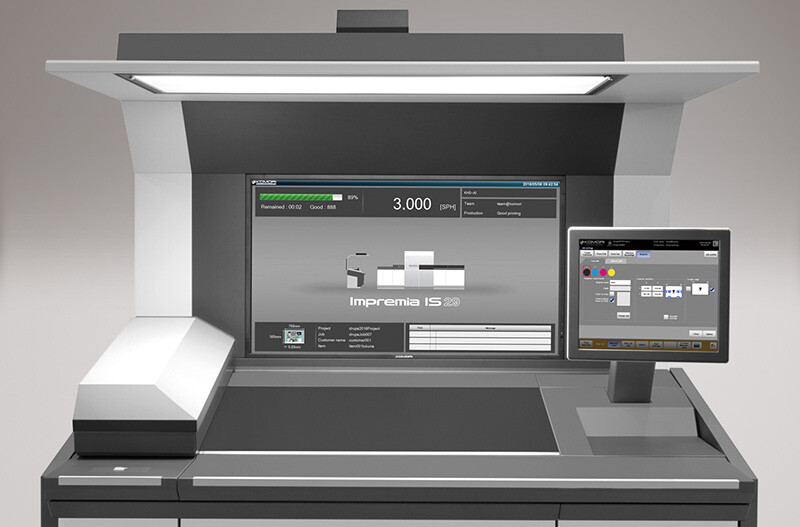

The Impremia IS29 at drupa 2016 was standing room only from start to finish. The hottest thing in Düsseldorf then is now changing the printing world with numbers and colors never before imagined. Production-ready.

What is the state of play in printing, and digital printing specifically?

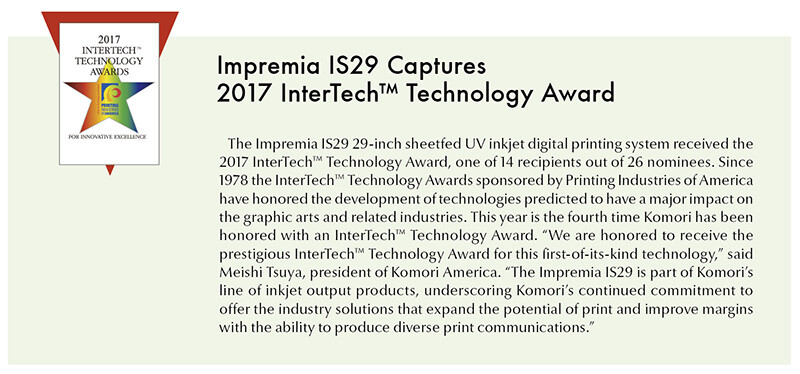

The world's printers require printing systems with a vast array of characteristics and applications. Five or six years ago, conventional offset presses were used mainly for commercial and publishing printing, and UV presses were introduced for package printing. Now the need for short runs of many different items, quick turnarounds and labor saving is growing more intense, so Komori is directing its efforts to the H-UV instant curing system. Around 800 H-UV presses have been installed globally. Also, H-UV L (LED) machines with an LED lamp used in place of a conventional UV lamp have been added to the lineup. More and more companies are installing these presses. As the printing environment rapidly changes, I feel that expectations are rising for digital printing systems that can meet clients' distinctive needs. The start of the digital printing business for Komori was the launch of Impremia C series systems at IGAS 2011. The flagship model Impremia IS29, which employs UV inkjet, was exhibited at drupa 2016 and China Print 2017, and global sales are under way.

What about the Impremia NS40 shown at drupa?

The Impremia NS40 is a 40-inch aqueous inkjet machine that uses the Nanographic Printing® System. With a high maximum printing speed of 6,500 sph, the machine offers offset-level productivity. Following beta testing, the Impremia NS40 is expected to be available in 2018 with options such as an in-line coater, seven-color printing and double-sided printing.

How does digital fit in with offset?

In the printing plant, the unique feature of Komori digital printing systems is the ability to be combined with offset presses and used in new business models. These systems can print short runs of many different items, manage variable data, handle ultrashort turnarounds, and just like offset, they are compatible with a wide variety of paper types and thicknesses. K-ColorSimulator makes color matching with offset printing very easy. These digital printing systems are flexible and capable of high print quality, from proofing to final production.

How can digital produce offset quality?

Color matching of offset and digital is quick and simple. Specifically, by connecting a color measuring device and K-ColorSimulator, a device link profile can be created automatically from the profiles of the offset press and the digital printing system. A printed item with the same quality as offset can be printed on the Impremia IS29 using this profile. And the Digital Station will be launched this fall as an option. By equipping PDC-SX on the Digital Station, a B2 size profile can be ready in a few minutes. Matching accuracy will be markedly better.

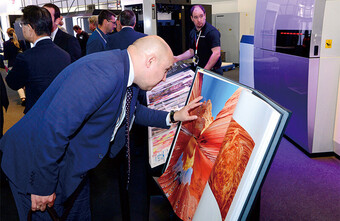

Impremia NS40 demonstrating the awesome Nanographic Printing® System to a packed house at drupa 2016. Options will include coater, seven-color printing and duplex.

What's unique to digital print?

Digital printing systems, of course, offer unique print capabilities such as variable data printing and versioning, which are already used by many companies. Another powerful feature is full gamut RGB printing, which is often employed for photo books and albums. In fact, Komori systems are implemented with Pantone and DIC Color Guide-compatible applications.

I've heard that register accuracy is a problem for digital printing systems.

Register accuracy is sometimes considered a weakness of digital printing, but actually register accuracy is critical for every kind of printing. Komori is a press manufacturer, so we are fanatical when it comes to register accuracy. Our sheet transport technology for offset presses has been transplanted intact to the Impremia IS29, so accuracy is high and extremely stable. The sheet reversing mechanism is standard on this system, and register accuracy is identical to offset even in duplex mode.

Scheduled for launch in autumn 2017, the new Digital Station will slash the time needed to create color profiles and enhance matching accuracy

How about printing speed when the number of special colors is increased?

Printing speed is never compromised with the Impremia IS29. It is often said that the printing speed on a digital system falls off when the number of special colors is increased, but since the ink of the Impremia IS29 has a wide color gamut, it can print specials with four colors, so there is no change of the printing speed. And the speed stays the same whether printing on ultralight or ultraheavy stocks, from 0.06 mm to 0.6 mm.

Is the Impremia IS29 limited with respect to substrates?

The system incorporates the concept of 'substrate freedom' by allowing a wide variety of stocks. This enables printing on materials such as coated, matte and high quality paper or even plastic substrates with advance testing. The stock used in offset printing can be printed with this machine stress-free. Count on it.

Demonstration of color matching by offset and digital

How should offset printers approach digital opportunities?

In today's world, digital media is growing exponentially with smartphones and tablets, and ways of conveying information are also changing. Needs and tastes have diversified, and now people are looking for originality. Printers' clients are focused on personalizing their product range and now concentrate on monozukuri that emphasizes premium value. I believe the era of just good monozukuri is over. High quality must be standard. Monozukuri that fits the times and delivers the highest quality is vital. Companies must make the most of every technique and strive to attain that extra special something.

What´s being asked of printing companies?

It's not as though offset presses are going to be completely replaced by digital systems. But many companies use offset presses as their mainstay, and so they only take orders for offset printing. To make the most of digital, it must be part of the business model.

Specifically, what sort of business model?

One example of a new business model would be presenting to a client the idea of test marketing by area or target group. The design favored by the market or users would be mass produced on an offset press, and small volumes for limited areas or time periods could be produced on digital.

Another business model aims at capturing orders for ultrashort runs and ultrashort turnarounds -- these have been growing in the past few years. Offset printers tend not to take jobs with such small volumes and tight turnarounds. While this work involves time and trouble, there are no discounts and margins are often high. If the printer can get an order for an ultrashort-run job together with a large job from a current client, the trouble is minimal, the risk is low, and more orders will follow.

Samples for new business model

So how will digital printing systems fit into the production setup?

Digital systems, of course, must be connected with prepress and postpress. Komori links digital systems, prepress, offset presses and postpress equipment with KP-Connect, which makes printing ultraefficient through use of the Internet. Postpress equipment differs widely according to the application -- varnishing and laminating lines, guillotines, die cutters and bindery equipment. Komori plans to make these processes near-line, and in the future offer both in-line and near-line choices.

What about postpress for the Impremia IS29?

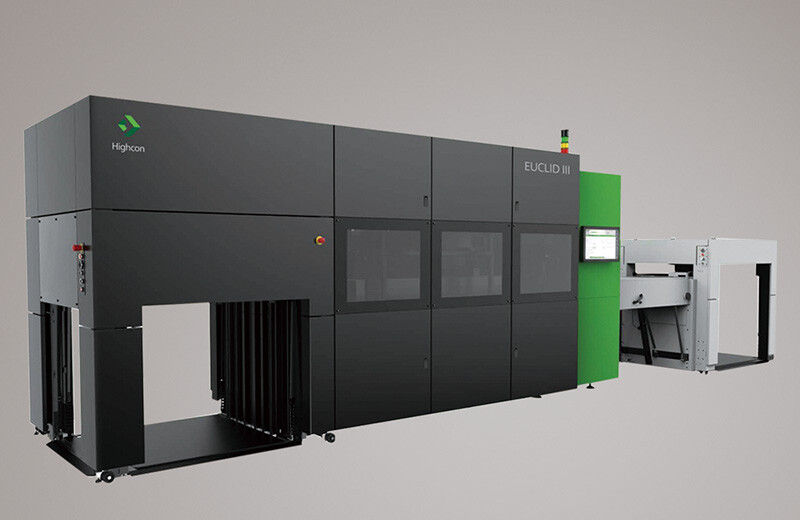

One new development in postpress is Komori's strategic business partnership with Highcon of Israel, the manufacturer of the Euclid series digital cutting and creasing system. This system permits cutting and creasing without using a knife, so it is ideal for a digital printing system.

Highcon's Euclid III Digital Cutting and Creasing System

How has the market responded to the Impremia IS29?

We've had inquiries from all over the globe on the Impremia IS29. The number of back orders at present is two figures. As one example of an installation, Artron's Beijing Plant is using the machine for web-to-print photo books in a B2C setup. They are also using it to print the works of painters and other artists and to create very large limited-edition collections of high quality photographs.

What are the future prospects for digital and the industry?

Change is coming, but not overnight. According to one survey, digital printing systems will account for 3-5 percent of output in 2020, while offset presses will take more than 90 percent of the market. Thus, barring something very unexpected, we do not see all printers switching to digital. But we do think that certain segments will shift to digital. In the field of data printing, for example, processes such as printing the frames with offset and then printing the varying parts with digital will change to full variable. We know that many commercial and packaging printers want to be able to do versioning, with content changing according to the customer. Komori will meet all these needs: those suited to the combination of offset and digital solutions as well as those leading to the development of new business. Komori knows printers very well, and we plan on continuing to be the most trustworthy player in printing. We will do everything in our power to meet the needs of printers.

-

Sample of Impremia IS29

-

Sample of laser cutting by the Euclid III

-

Artron Big Book gathers a crowd at drupa 2016