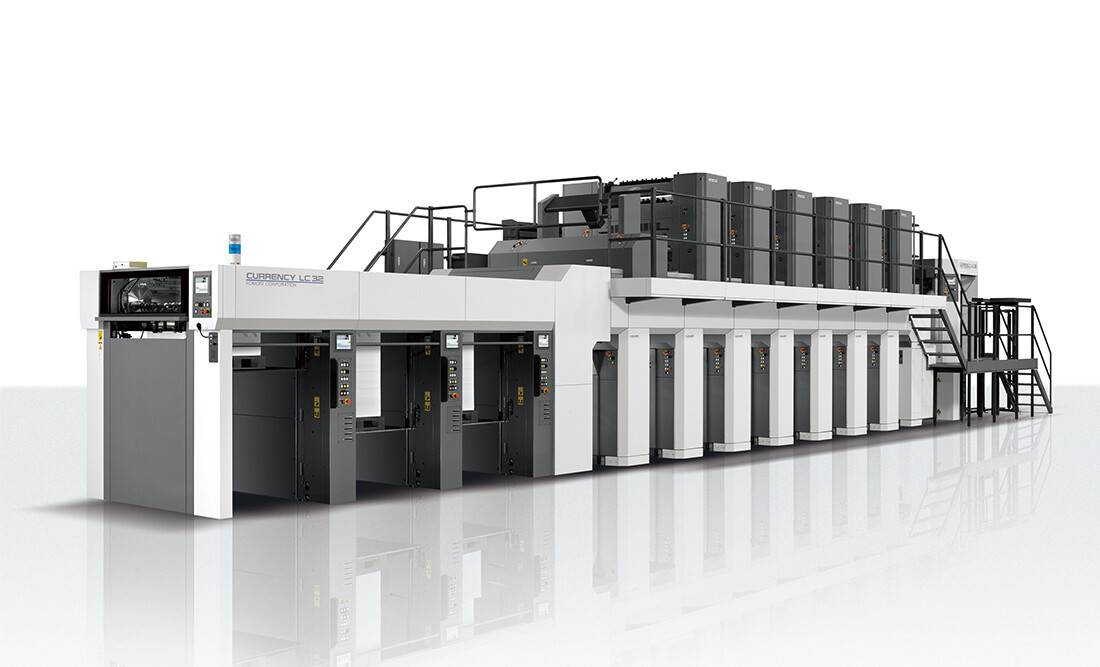

CURRENCY LC32

September 2017 saw the issue of the new sterling polymer £10 banknote by the Bank of England, following on from the highly heralded issue of the Bank's first polymer note, the sterling £5 denomination, issued in September 2016.

The new £10 note is printed at the Bank of England's purpose-developed 100,000 sq. ft. Debden site, where the four denominations of sterling notes are produced by Debden Security Printing Ltd, a subsidiary of De La Rue Plc. The £10 note has created immense public interest not only because of its enhanced security resilience but also because it features a portrait of iconic early 19th-century British novelist Jane Austen, writer of such famous works as Pride and Prejudice. Interestingly, there was an earlier Austen-inspired £10 note issued in the UK, but that was on paper and over 200 years ago by Jane's aristocratic brother, The Reverend Henry Thomas Austen who co-founded a bank business in 1804 and was Jane Austen's financial mentor!

Polymer — pushing the design boundaries

Polymer banknotes deliver significant benefits, particularly when combined with state-of-the-art security features that make the notes much harder to counterfeit. Says De La Rue's Head of Design Alan Newman: "Polymer is an ever-evolving product that gives us great capacity for innovation and design integration. The layer construction enables our designers to push the boundaries that integrate with the print design in a way that has never been possible before to provide exciting, increasingly secure products."

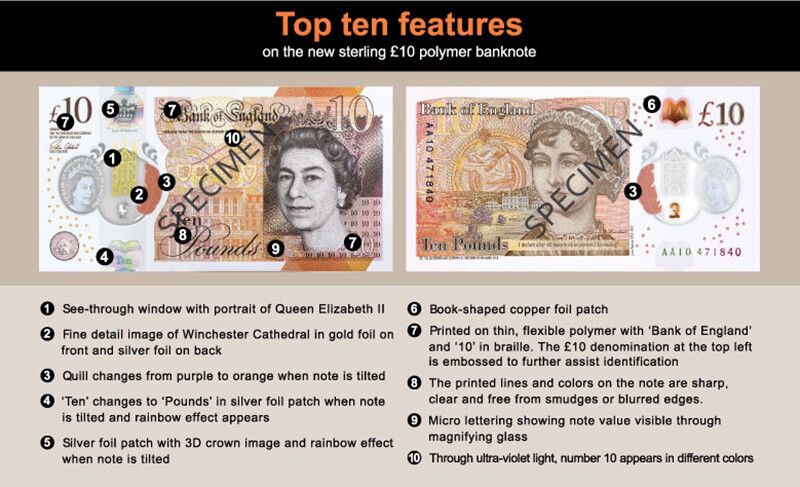

The new £10 note includes, for the first time on sterling banknotes, a specific tactile feature to help blind and partially sighted people to identify the notes. This is in addition to the elements already incorporated for vision-impaired people, such as bold numerals, different colors and sizing. Our top 10 features graphic illustrates the complexity of the security features and the ingenuity of the design team.

The fine detail of many of these features requires every element of print to be of the highest quality, precision and consistency. Komori is very proud that the new £10 note is printed on the Bank of England's new Komori banknote production lines. Each of the two lines consist of the LC1232 12-unit double-deck offset press, the IC532III intaglio press, the RN332III numbering press and the GL40CC varnishing perfecting press. Additionally, at Debden, De La Rue has installed a Komori Currency RC32III rollercoater.

De La Rue's Gateshead production line

CURRENCY IC532III

In 2014 De La Rue was awarded a 10-year contract by the Bank of England to print its banknotes at Debden, and the new £10 note was created by De La Rue's design team, which is responsible for the design of around 40 percent of the banknotes currently in circulation around the world. The company is the biggest producer of banknotes and passports in the world. It prints over seven billion banknotes annually and has offices across four continents and manufacturing facilities in Kenya, Sri Lanka, Malta and at two sites in the UK — Debden and Gateshead.

At De La Rue's Gateshead facility, a new Komori production line was inaugurated in October 2013. The line consists of the Komori Currency LC32 multi-color double-deck offset press in 12-unit configuration, the Currency IC532III multi-color intaglio press, the Currency RN332III three-color numbering press and the Currency 40CC varnishing perfecting press.

Says Andrew Parr, De La Rue's Manufacturing Technical Director: "The Bank of England contract was extremely important for De La Rue to win, and we had to respond to a very specific competitive tender. Partnering with Komori enabled us to match the requirements and on the back of the successful installation of our first Komori line in Gateshead, we felt extremely confident in the solutions from Komori."

"The Komori production line provides us with the opportunity to maximize the designs of the new polymer note, taking advantage of additional print workings. Probably even more significant is the performance of the printing presses in running polymer, which does present new challenges, especially regarding the handling of the substrate and the blocking. Komori's sheet feeding and delivery systems have performed extremely well, enabling us to deliver a quality product to our customer on time. Now, with the Bank of England going polymer, it will be interesting to see whether this accelerates its uptake in the market, which still remains relatively low."

Komori banknote technology worldwide

Komori is the sole manufacturer of banknote printing presses in Japan and delivered its first banknote printing machine to the National Printing Bureau of Japan in 1958. In the 1980s, Komori commenced supply of security and banknote lines to territories outside Japan and now has lines throughout the world, including Korea, China, India and Nigeria, with the most recent installations in the Philippines, Indonesia, Vietnam, Russia, Bulgaria, the UK and Malta.

Comments Komori Corporation's Takeo Uehara, General Manager, Security Press Sales Group: "With De La Rue, we don't consider that we have a buyer/seller relationship. It's a true partnership and works as such, with both parties cooperating closely and constantly to benefit current production requirements and to further future development. The De La Rue Gateshead production line installation provided us both with the confidence to commit to the new Debden lines, which, like the Gateshead line, have the Currency LC32 double-deck machine at their core. LC32 technology was developed in 1997 and its availability in 4-over-4, 5-over-5 and 6-over-6 unit configurations provides the flexibility for wet printing to be split between different units to best suit the elements and content of the design. This versatility helps ensure that print production is able to meet those increasingly creative and innovative anti-counterfeiting features that banknotes are expected to incorporate in the future."