Crestec ramps up package production with Lithrone G44

Indonesia, CRESTEC Indonesia | Lithrone G44 [GL-644+C UV/IR]

01 April 2019

CRESTEC is located in Shizuoka, the prefecture home to Mount Fuji, sacred to the Japanese, immortalized by poets and painters, and since 2013 a UNESCO World Heritage Cultural Site. Helmed by President Akira Takabayashi, the company began translation and printing of multilingual technical documents, such as user manuals, with a global footprint and a clientele of primarily Japanese

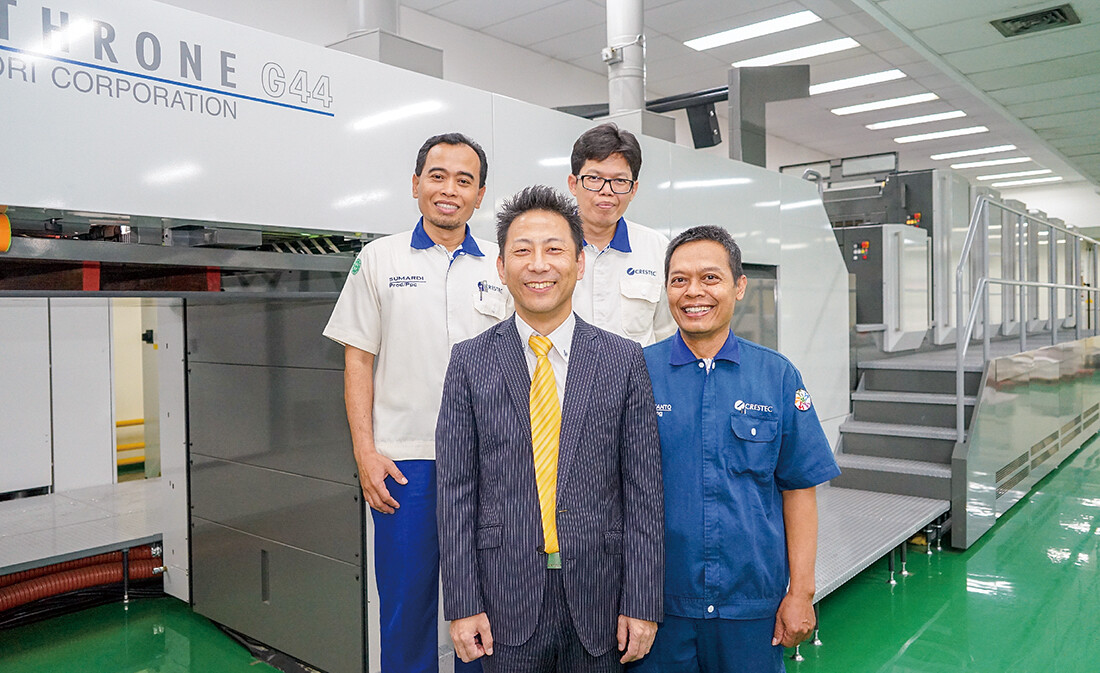

From left: Sumardi, Production Supervisor Head; Naoki Dohaku, President; Arif Budiman, Production Assistant Manager; Siswanto, Printing Supervisor

Around 2014, CRESTEC launched an orderly growth strategy of expanding new business for its 11 sites in Japan and its 20 locations in 11 other countries. As one element of this strategy, CRESTEC began package printing at the Jakarta Plant of PT CRESTEC Indonesia, the company's largest overseas subsidiary. Once orders increased, it installed a six-color Lithrone G44 UV/IR press with in-line coater and the PQA Print Quality Assessment System and ramped up production.

President Naoki Dohaku has set a striking goal for the investment in this press: "I want to ensure that the importance of production speed, high added value and quality control gets through to all employees so that we attain our highest ever sales."

Expanding orders through speedy, proactive sales

CRESTEC was founded in 1984. As customers began to shift operations to other countries in the 1990s, calls to reduce the cost of printing technical documents grew, and the company began to move production overseas. Presently, it operates its own printing plants and sales offices in North America, Europe, China and Southeast Asia.

CRESTEC Indonesia runs plants in Jakarta and Surabaya. The Jakarta plant is the group's largest, with some 350 employees. Before the most recent installation, the plant operated a five-color 44-inch press and four-color and two-color 40-inch presses, all printing with conventional ink.

The company recorded its greatest sales in 2009. Following that, cost pressure from customers increased, and orders for documents were dispersed throughout the world to reduce risk. About five years ago, to shore up its business, the Jakarta plant began color printing on light stocks for magazines and similar work, then gradually started taking orders for package printing — and sales showed signs of recovery.

President Dohaku, appointed in 2016, strongly supports package printing as the concrete plan for new business. "Documentation is more and more being replaced by electronic media, but packaging is a growing segment. It's necessary to develop this with a sense of speed," he says.

Pursuing orders is also done with an emphasis on speed. The company tries to become engaged when a customer is in the new product development stage by quickly making proposals for package design and construction. By installing a sample cutter, it can present a prototype in as little as one day, enabling it to get a head start on competitors. Orders from local firms and overseas companies are on the increase.

40 percent increase in jobs, 3-hour work speedup

Not only are orders increasing steadily but also large-scale projects for global rollout are making progress and installation of presses specialized for package printing is on the fast track. Mr. Dohaku explains why the printer selected a Komori press, "The Lithrone G44 was best suited for small cartons for consumer goods, which make up the core of our orders. In terms of size, Komori was the only choice. With regard to specifications, nearly all of the jobs require coating and two special colors. We were losing a great deal of time by having to make multiple passes, so our biggest priorities were an in-line coater, one-pass printing and maximizing production efficiency by UV printing."

The new press along with a die cutter and gluer is installed in a space divided by partitions. The system takes sheets that are instantly dried by UV curing to the adjacent postpress area and then onto finishing. "By getting this speed, we've been able to really prevail against the competition," says Dohaku.

Printing Supervisor Siswanto also has high praise for the new machine: "We are doing 40 percent more jobs than we did previously." Production Assistant Manager Arif Budiman adds with a smile, "Due to insufficient experience in operating this press, the time for settings is still not much different than with our previous machine. However, due to the in-line coater and the instant UV curing, our impression is that daily work is about three hours faster than before. We're counting on this for the future."

Lithrone G44: Core for further added value

CRESTEC Indonesia is now concentrating work on the new press. "I am directing all new jobs and all runs that are longer than 10,000 sheets — even if they are not packaging work — to be printed with UV. Our ability to meet short turnarounds will grow, and our use of conventional oil-based presses will be enhanced," says Dohaku. He is aiming for a ripple effect, saying, "I want our operators to experience the speed and be inspired even on our other presses."

The plant is also taking on a variety of high added value work that takes advantage of the characteristics of UV printing. Printing on aluminized paper has already been commercialized. "Right now we're testing various kinds of printing, such as plastic substrates, spot varnish and drip-off effect," says Mr. Siswanto. "We're getting technical guidance from Komori, so we want to quickly make these technologies our own. They've almost never been seen in Indonesia," says Mr. Budiman enthusiastically.

Also, the PQA system will soon be deployed as a new weapon. According to Dohaku, inspection standards are presently set for jobs where the highest quality is required. "However, we want to set standards for each product, efficiently remove defective sheets according to the customer's demand and assure high quality," he says.

Since installing the UV press, the morning meeting where ideas are bounced off of each other has become spirited. President Dohaku says, "If ideas from the plant floor are made reality, CRESTEC Indonesia will be reborn with great strength." Everyone in the company is on board and all set for the effort to attain the highest ever sales.