Sirivatana: Mammoth Thai Printer adds two high-spec Lithrones

Thailand, Sirivatana Interprint | Lithrone G40 / Lithrone G44 [GL-640+C UV · GL-844+C]

01 April 2019

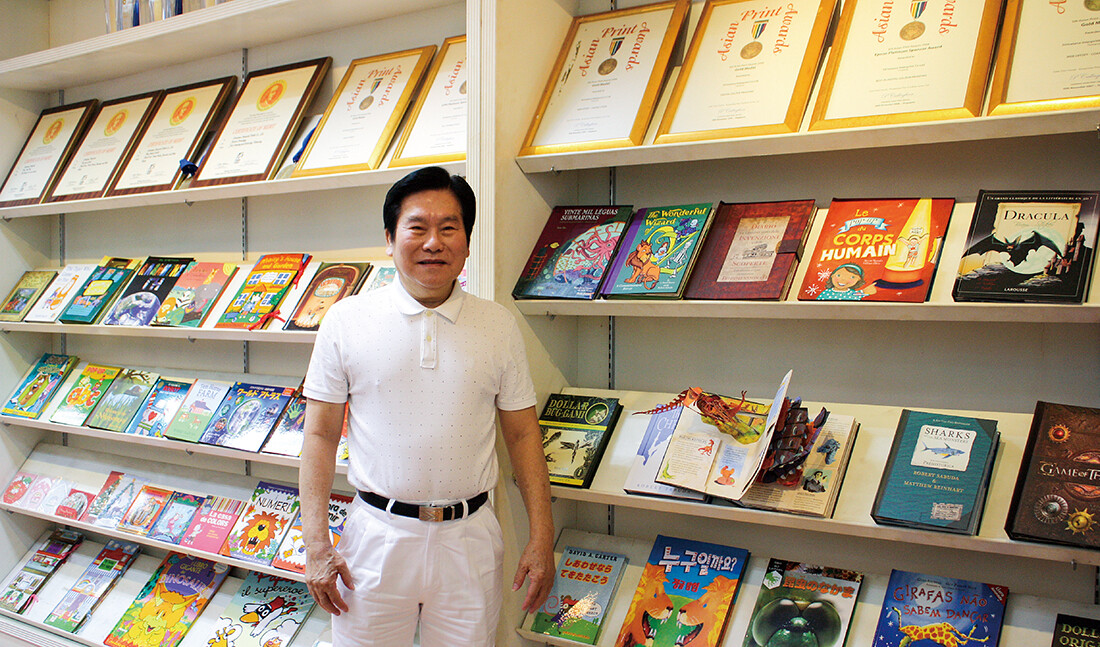

The origin of Sirivatana Interprint Public Co., Ltd. can actually be traced back to the first job ever landed by Pornthep Samatiyadekul, the company's founder. "After working at a shipping firm for 10 years, I'd gained sufficient experience and was ready to start my own business."

Pornthep Samatiyadekul, President

"After I'd seen all the beautiful details of international printing work, I chose to open a printing business. I started on a small scale by running the business in my house with only one small printing machine and two employees," says Mr. Samatiyadekul.

In a few years, his business started to grow rapidly, and he had to expand from operating from home to renting a shop. "I had a lot of friends from the shipping industry who became my customers in the first few years," he says. Now his company is one of the biggest printing houses in Asia, with more than 3,000 employees serving both Thai and international customers.

Marketing principles

"Our marketing strategy is to focus 70 percent of our resources on the international market and 30 percent on the local market. However, our customer base in Thailand has grown rapidly in the past few years, so we have adjusted our strategy to focus more on the Thai market. Being a player in the international market has given me an understanding of the level of quality required," Samatiyadekul says.

Apart from making a profit in his own business, Samatiyadekul always repays society through his CSR (corporate social responsibility) activities. "We run charity jobs every weekend, especially for the underprivileged. We donate wheelchairs, money and educational support to shelters. Moreover, during the enormous flood disaster in 2011, Sirivatana's management team donated to the victims both directly and via the government," he says.

Expansion to packaging and security printing

Boontham Siriso, Production Director

Due to the downturn in commercial printing over the past 10 years, the management team decided to establish Siri Media to support digital printing, which is a growing business, and also Sirivatana Security Printing to produce security printing jobs such as passports, bank checks and confidential government documents. Soon after, Sirivatana expanded to neighboring countries and decided to invest in two state-of-the-art high-tech printing machines, a six-color Lithrone G40 UV press with in-line coater and an eight-color Lithrone G44 press with in-line coater, to print packaging jobs, an area that continues to grow. This brings to 21 the number of Komori presses in operation at Sirivatana.

Production Director Boontham Siriso explains the background to these investments: "For several years, Sirivatana Interprint was trying to make a deal with a well-known customer. However, print quality with our existing equipment did not meet the customer's requirements. We decided to purchase the six-color Lithrone G40 UV with coater and the eight-color Lithrone G44 with coater to achieve the needed quality. After receiving the new Komori presses, we were able to conclude a long-term contract with this customer."

These investments were driven by print quality, waste paper reduction, time saving (only 30 sheets are used for register adjustment), color consistency and accuracy. Moreover, only two to three operators are needed for each machine and the presses run 24/7.

In addition, customers with stringent quality standards have been very satisfied. For example, food packaging work has grown by 40 percent, with these two machines playing an important part.

Mr. Siriso describes his impressions of Komori printing presses: "Our opinion of Komori machines has always been great because it was the first printing press we used back when the company was established. Nowadays at our company, Sirivatana Interprint PCL, there are a lot of presses, and still about 90 percent of the machines are from Komori. They are not only easy to operate but the manufacturer also provides an on-site expert for training. This really helps to reduce the lead-time for learning how to operate the new machines. Hence, it will be easy to make a decision on purchasing more machines from Komori in the future. It can also be said that part of the success of Sirivatana Interprint today is from Komori."