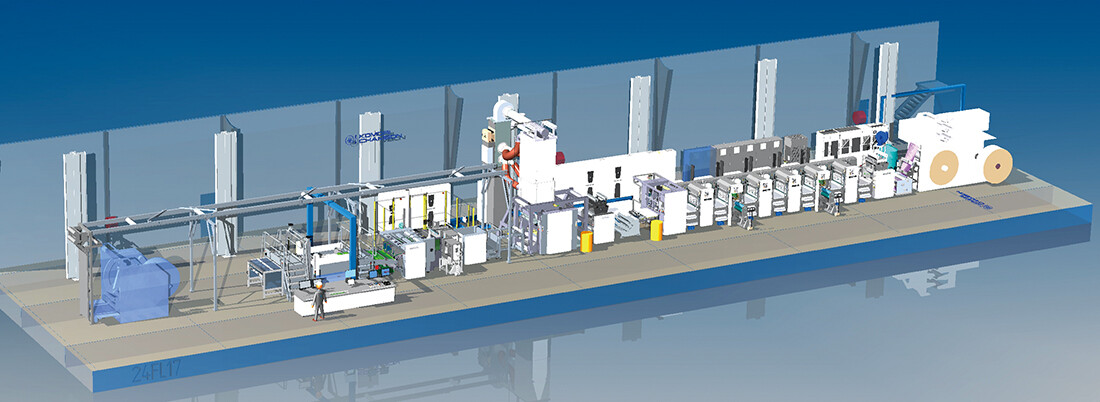

KCM production line, from the unwinder to the stacker delivery in the typical right to left layout. KCM is the master of all printing processes and can combine them, like here with a flexo unit after the offset units for varnish management.

Founded in 1887, Machines Chambon, a long-established packaging specialist in inline printing and converting solutions joined the Komori group in 1989 as Komori-Chambon. Laurent Bince, CEO at KCM, explains, "Inline webfed solutions allow a seamless production flow in roll-to-roll or roll-to-blanks configurations. All jobs are completed in seconds, without any interruption or human action."

Production speeds can reach 450 meters per minute (equivalent to 27,000 sph with a 40-inch sheetfed press), without any loss between printing, converting and delivery stages. Rotary die-cutting and delivery sections can be set up inline with any third-party machine.

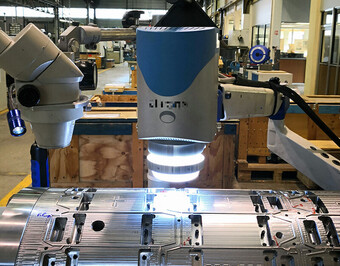

Komori-Chambon designs and manufactures all key components in France, including machines and tools for both printing and cutting. KCM machines achieve precision levels of less than 10 microns in grinding and engraving with cylinders of up to 3 meters and weighing up to 4 tons.

"Our manufacturing skills are augmented by our capacity to integrate any equipment, offering the best performance for any application. Ultimately, the most important point is mastering carton board from A to Z. On board from 50 to 600 gsm and up to 32 points, quality printing and high precision converting are Komori-Chambon's commitment," says Mr. Bince.

Over 130 years of experience and tremendous flexibility allow KCM to make the most of opportunities in mature as well as new markets, where packaging innovations require responsive and reliable solutions.

-

KCM’s high precision manufacturing and extremely rigorous standards guarantee a long service life and rock-solid performance.

-

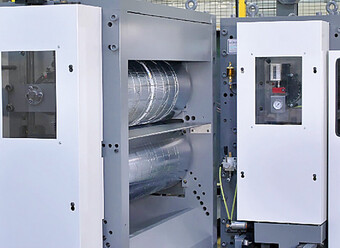

KCM rotary die-cutters are perfect for embossing, creasing, cutting, and stripping applications.